The Potential of Lithium-ion Batteries Is Huge Indeed, These Are Some Technical Aspects – Koyel Ghosh.

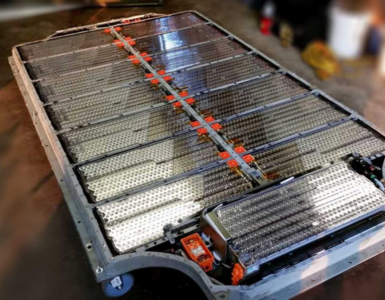

Lithium-ion batteries are rechargeable in nature, with high energy density. These batteries are mainly used in portable electronic devices. The global lithium-ion battery market growth is driven by an increase in use of various automobiles such as electric & hybrid vehicles. In addition, the product demand is expected to rise across electrical & electronics industry, owing to surge in penetration of smartphones and laptops.

According to Allied Market Research, the global lithium-ion battery market is expected to register a significant CAGR from 2019 to 2027. Li-ion batteries are extensively used in electronic devices such as personal computers, smartphones, laptops, cameras, and so on, owing to their extended service life and high energy density. Among all electronic devices, laptops and smartphones are the major kinds that use li-ion batteries. In today’s scenario, effectiveness of batteries is one of the most important features required to ensure the increasing sale of electronic devices in most countries. Mainly, tablets and personal computers are experiencing higher sales, in comparison to other electronics. This is due to their enhanced performance coupled with low-slung prices. At the same time, battery back-up is deemed to be one of the major features consumers tend to enquire before purchasing any tablet, PC, and mobile phone. As Lithium-ion batteries offer top battery life, they are highly preferred in manufacturing smartphones.

A recent post published in the journal Materials Today Nano describes an inventive approach to formulating composite materials to be used in next-gen li-ion batteries. Intuitive solutions make use of silicon cutting waste powder by thriving nonporous amalgams of silicon which can then be utilized to produce high magnitude li-ion resistors.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

The impact of the multi-porous carbon layers, silver units, and Si matrix tend to improve the overall performance of silicon-nanocomposite-based capacitors by increasing the transmitting capabilities and improving lithium-ion dispersal efficacy and structural cohesion.

Electro-optic silver cation discharge during manufacturing is important for the development of disseminated silver nanoparticles. The fabrication of permeable Si configurations with consistent spreading of Ag nanoparticles is facilitated by nanometal aided etching process, making this a prospective technique for formulating silicon-based nanocomposites for inductors in lithium-ion series.

A lab-scale production of Lithium-ion batteries has recently been devised in Bangalore. ARCI, an independent and self-directed Research & Development Centre of DST, took on a contract & settlement for technical transfer of knowledge and training of workforces to establish the Lithium-ion battery fabrication laboratory on November 25, 2021.

The knowledge transfer was solely based on the proficiency developed in setting up Li-ion battery course and its effective demonstration about how the batteries have been useful to electric scooters and solar street beacons.

The main players operating in the global Li-ion battery market are persistently adopting numerous strategic moves including joint agreements, development plans, company acquisitions, along with several combined ventures, to retain their position in the market. For example, back in 2017, Maruti Suzuki India Ltd. joined forces with Denso Toshiba to kick off a li-ion battery production factory in India.

One of the apparent disadvantages of working with li-ion batteries has been that these batteries cannot be reprocessed, and thus each new cell calls for fossil-fuel-powered energy-exhaustive mining of ores such as cobalt, nickel, and manganese.

It not only intensifies the emission of greenhouse gases from the battery supply chain, but it also causes concerns over the future shortage and cost of these raw constituents. At the same time, human rights issues also come up as a threat, specifically since more than seventy percent of the world’s cobalt supply hails from from the Democratic Republic of Congo, where excavating has seen lethal mishaps, child labor, and intense clashes between poor miners, as well as local sleaze and exploitation.

Nevertheless, a development in battery reprocessing may now have been attained, especially with a Sweden based firm Northvolt proclaiming that it has created its first li-ion battery cell utilizing hundred percent recycled cobalt, nickel, and manganese — the most essential components in NMC series.

COVID-19 scenario

The outbreak of the COVID-19 gave way to disrupted supply chain in the majority of countries, which in turn led to distorted production facilities, thereby impacting the global li-ion batteries market negatively, especially during the initial phase. Scarcity of raw materials and temporary ban on exports and imports aggravated the situation yet more. However, as the global situation is getting better, the market is anticipated to recover soon.

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing on miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest for creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last four years.

READ the latest news shaping the li-ion battery market at Batteries News.

Copyright © Batteries News. All Rights Reserved.