Study by VDMA and Porsche Consulting on battery factories.

More than 200 battery factories are expected to be built worldwide in the next ten years, a majority of them in Europe. And each of these factories requires production technology worth billions.

There is a historic growth opportunity for German and European mechanical and plant manufacturers. A new study by Porsche Consulting in collaboration with the VDMA shows how it can be used.

Electric drives play a crucial role in the future of mobility worldwide, this is particularly true for road traffic. The green electricity for this will largely be stored in batteries. The market for such power storage devices, mostly based on lithium-ion technology, will grow globally from around 20 billion euros per year today to around 550 billion euros annually by 2030. The speed of growth is breathtaking: While the semiconductor industry once needed around 40 years for this development, it will only take around ten years for batteries.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

200 battery factories under construction worldwide

Around 200 battery factories are under construction or planned worldwide. They are currently equipped primarily with production technology from Asia. Chinese mechanical engineers are currently setting the standard as full-service providers. Only eight percent of the high-tech equipment in such factories comes from Europe. This proportion is too small to have a significant influence on technical development and to create a second cluster for battery technology in Europe. This would require a permanent market share of around 20 percent. This is proven by the analysis by the battery experts from Porsche Consulting and the VDMA in the current study “Battery Manufacturing 2030: Collaborating at Warp Speed”.

The study shows approaches to how technological dependency can be prevented in this future-critical field. After extensive analyzes of technology and providers, forecasts from our own market models and a series of interviews with market participants, it is clear that the cooperation of those involved plays a crucial role.

Gregor Grandl, senior partner at Porsche Consulting and co-author of the study:

Only if European mechanical engineers succeed in jointly offering integrated factory solutions will they be able to assert themselves against the competition from Asia.

“Technologically, the European industry is at the same level, but companies from China are already offering entire battery factories on a turnkey basis.” This reduces interfaces and thus the time and financial risk during construction.

The opportunities for mechanical engineers are huge: to maintain a market share of just eight percent in the battery market during the rapid ramp-up, annual growth rates of 33 percent would be necessary. In order to achieve a 20 percent market share, companies would have to grow faster than the market. An increase in sales of around 50 percent per year would be necessary – and possible. The market volume by 2030 for mechanical and plant manufacturers in the battery sector alone will be 300 billion euros. Success in this competition would ensure Europe’s long-term access to the important future technology of batteries and create many jobs in the process.

German and European mechanical engineering companies have recognized this and are actively addressing it.

Hartmut Rauen, Deputy General Manager of the VDMA, said:

The foundation of our industry lies in the close cooperation between mechanical and plant engineering and its customers.

“This partnership creates not only knowledge, but also innovation.”

Growing demand for innovative battery production solutions

Highly specialized companies such as Manz AG from Reutlingen are consistently pursuing this path:

Martin Drasch, CEO of Manz, said:

As a European mechanical engineering company, we have made targeted investments in battery production in order to be prepared for the rapid market ramp-up shown in the study.

“Through the joint venture with the Dürr and Grob companies, we are strengthening our position in the market and can respond efficiently to the growing demand for innovative battery production solutions for gigaprojects.”

Stephan Eirich, managing partner of Maschinenfabrik Gustav Eirich GmbH, said:

The high demands of customers on turnkey suppliers require a rethink in the ramp-up phases for this industry.

“This represents a new challenge, even for experienced mechanical and plant engineers, which we are taking on.”

VDMA

The Association of German Mechanical and Plant Engineering represents more than 3,600 German and European mechanical and plant engineering companies. The industry stands for innovation, export orientation and medium-sized businesses. The companies employ a total of around three million people in the EU-27, including more than 1.2 million in Germany alone. This makes mechanical and plant engineering the largest employer among the capital goods industries, both in the EU-27 and in Germany. In the European Union it represents an estimated sales volume of around 860 billion euros. Around 80 percent of the machines sold in the EU come from a production facility in the internal market.

VDMA Robotics + Automation represents one of the most dynamic and fastest-growing sub-sectors of mechanical engineering. It is made up of the three specialist groups Robotics, Industrial Image Processing Vision and Integrated Assembly Solutions. Its 400 member companies are manufacturers of assembly and handling technology, industrial image processing and robotics.

VDMA Battery Production brings together 170 member companies that address production technology for batteries of all technologies, with the current focus on lithium-ion technology.

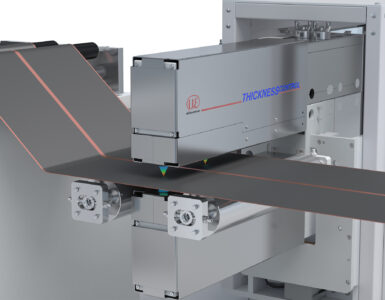

The member companies supply machines, systems, components, tools and services along the entire battery production process chain: from raw material preparation through electrodes, electrode production and cell assembly to module and pack production.

Porsche Consulting

Porsche Consulting GmbH is one of the leading consulting companies in Germany. It was founded in 1994 as a result of Porsche’s rise to one of the most profitable and respected manufacturers of sports and luxury cars. Today, the experts support companies worldwide with strategic transformation and performance management. Management consulting clients come from the automotive, aviation, transportation, industrial goods, pharmaceutical and medical technology, consumer goods, construction, energy and financial services sectors. From locations in Germany, Italy, France, China, Brazil and the USA, Porsche Consulting offers outstanding expertise in the areas of strategy and organization, operations, brand and sales as well as technology and development.

READ the latest Batteries News shaping the battery market

Study by VDMA and Porsche Consulting on battery factories. source