PEM Reduces Drying Time in Battery Production by Over 60%.

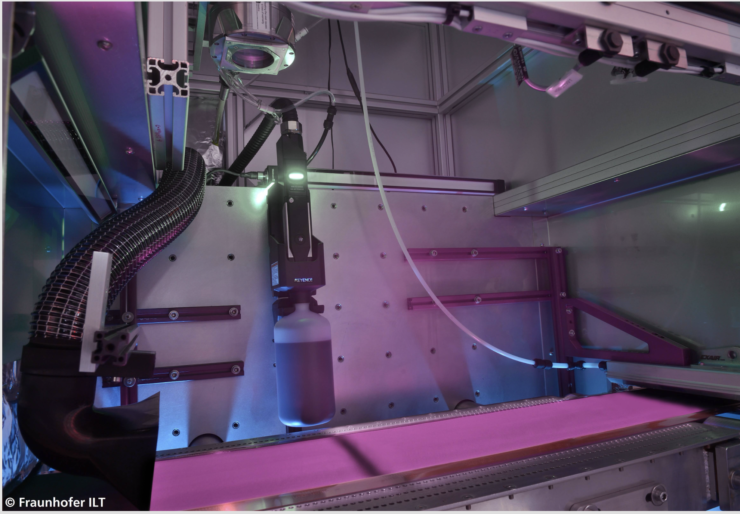

In the IDEEL research project, the Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has succeeded in reducing the drying time for LFP cathodes and graphite anodes of lithium-ion batteries by more than 60% thanks to an innovative laser process, thereby significantly reducing energy requirements. As part of the joint project funded by the German Federal Ministry of Education and Research, the Fraunhofer Institute for Laser Technology (ILT) was able to double the web speed for coating and drying in a continuous process to five meters per minute. At the same time, the space required for the production step has been reduced.

Possible implementation on industrial scale

Achim Kampker, PEM Director Professor, said:

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

The research successes indicate that laser drying in the production of lithium-ion batteries can be implemented on an industrial scale in a technically and economically viable manner.

As part of the Implementation of Laser Drying Processes for Economical & Ecological Lithium-Ion Battery Production (IDEEL) project, since October 2021, partners from industry and research have been developing a laser-based drying process for a more climate-friendly and economical series production of lithium-ion batteries. By the projectʼs intended end on 30th September 2024, work is to be carried out, for example, on scaling up the drying process to up to 30 meters per minute.

Silicon-containing anodes to increase performance

In order to further develop the process in terms of materials, the Münster Electrochemical Energy Technology (MEET) Battery Research Center at the University of Münster is currently working on silicon-containing anodes to increase the performance of the batteries. In close collaboration with the researchers at PEM and Fraunhofer ILT, the new developments will then be tested for compatibility with the laser drying process and adjustments made, if necessary. Surveys among users from industry and research conducted by the project partners at Fraunhofer Research Institution for Battery Cell Production (FFB) will continuously provide new data on the current requirements for drying processes and enable practice-oriented development work.

READ the latest Batteries News shaping the battery market

PEM Reduces Drying Time in Battery Production by Over 60%. source