LiCAP Technologies, INC introduces the Activated Dry Electrode TM for solid state battery.

LiCAP Technologies, Inc. expanded a portfolio of technologies compatible with the proprietary Activated Dry ElectrodeTM process, unveiling a cost-effective and sustainable pathway for commercialization of the solid-state battery.

Solid-state battery (SSB) technology holds the promise of improved safety, increased specific energy, and energy density over conventional lithium-ion batteries (LIB).

However, the traditional “wet” coating approaches to electrode manufacturing used in the commercial production of LIBs are not compatible with the dry room processing of moisture-sensitive solid-state electrolyte materials.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

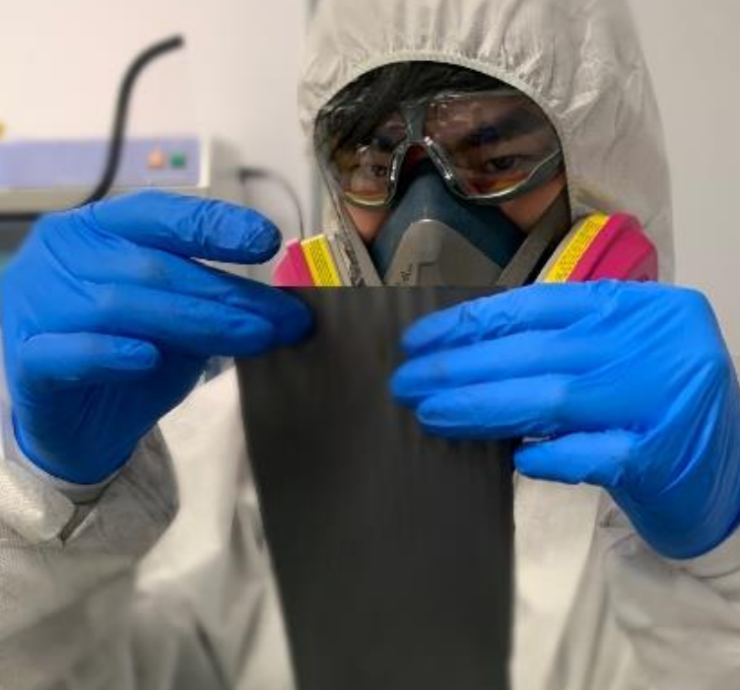

LiCAP successfully applied the Activated Dry ElectrodeTM technology to manufacturing of solid-state battery electrodes and produced first catholyte samples. Since the start of the trials in February 2022, LiCAP developed several SSB electrode formulations with NMC and sulfide-based electrolyte materials.

These materials were processed into stand-alone active layer films and laminated on aluminum

current collectors. At the current development stage, LiCAP can manufacture SSB electrode samples with the areal mass loading ranging between 26-60 mg/cm2 with high electronic conductivity.

Moreover, LiCAP’s engineering team determined that the developed SSB electrodes can be scaled-up to a pilot and large-scale production similarly to the already existing lines for lithium-ion battery and ultracapacitor electrodes.

Dr. Linda Zhong, the president of LiCAP:

The wet coating process is proven in the lithium-ion battery industry, but its compatibility with SSB is limited and the economics are flawed.

“Activated Dry ElectrodeTM technology can address the shortcomings of traditional slurry coating.”

“We are working on a breakthrough solution, which would open the automotive industry up to the next generation battery. Our preproduction line will produce SSB electrodes at a 60 m/min speed and will be commissioned in 2023”.

LiCAP’s Activated Dry ElectrodeTM technology will radically simplify SSB electrode manufacturing and yield dramatic savings and performance improvements over traditional wet coating.

From Hours to Minutes: Activated Dry ElectrodeTM process doesn’t require drying, solvent recovery or calendaring and removes entire steps in the manufacturing process while increasing the manufacturing throughput.

Drastic Cost Reduction: Activated Dry ElectrodeTM process removes energy-intensive manufacturing steps which contributes to lower CAPEX and OPEX. The small manufacturing footprint of Activated Dry ElectrodeTM line enables cost-effective manufacturing of SSB electrodes in a compact dry room.

Flexible and Modular: Manufacturers can scale in small steps to match supply to demand and be costeffective even at a low production volume.

Safe and Sustainable: LiCAP’s electrode manufacturing platform uses only a very small amount of nontoxic solvent for the activation step and with 100% recyclable electrode trimmings creates the most sustainable SSB electrode ever made.

Dr. Katharina Gerber, Director of Business Development for LiCAP.

Our Activated Dry ElectrodeTM process will help the solid-state battery industry to achieve performance, low-cost targets and, ultimately, pave the path to commercialization.

“Our pilot equipment is now available for feasibility projects on customer’s SSB materials at our facility located in Sacramento, CA”.

ABOUT LICAP TECHNOLOGIES, INC

LiCAP Technologies, Inc. is a leading developer of sustainable manufacturing solutions for electrodes used in lithium-ion batteries (LIBs), lithium-ion capacitors (LICs), ultracapacitors (UCs), and, most recently, in solid-state batteries.

The core technology, Activated Dry ElectrodeTM process, is applicable to manufacturing of low-cost premium electrodes for a variety of secondary energy storage applications. Co-founded and led by the original inventor of the “dry electrode” technology, LiCAP is headquartered in Sacramento, California and employs more than 150 people worldwide.

LiCAP’s ultracapacitor cells and modules are commercialized for a number of power applications. LiCAP’s battery electrodes are currently undergoing customer testing with world’s largest battery and automotive OEMs. For more information, please visit www.licaptech.com

READ the latest Batteries News shaping the battery market

LiCAP Technologies, INC. introduces the Activated Dry ElectrodeTM for Solid State Battery, Sacramento, CA, March 12, 2022