CUSTOMCELLS ® has successfully completed the review of battery binders from BASF. On behalf of the world’s leading chemical company, CUSTOMCELLS® evaluated the binders for graphite and silicon anodes in comparison to an established SBR binder, whose use is widespread in lithium-ion anodes.

Leopold König, CEO and co-founder of CUSTOMCELLS®.

With CUSTOMCELLS®’ many years of scientific expertise, we are happy to support other companies in evaluating innovative materials in an industrial and near-series environment with the help of our comprehensive testing capabilities.

“Together, we are advancing battery cell development and production ‘Made in Germany’ and working on the future viability of Germany as an industrial location.”

Overall, a comprehensive comparison of the binders developed by BASF for graphite and silicon anodes with regard to both processability and electrochemical performance was realized within the scope of the commissioned evaluation with the aid of prototype cells.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

The project focused on the processability of the binder using an industrial coating system for graphite and silicon anodes and the transfer to an established electrode coating process. The adhesion and other mechanical properties of the anodes produced were investigated.

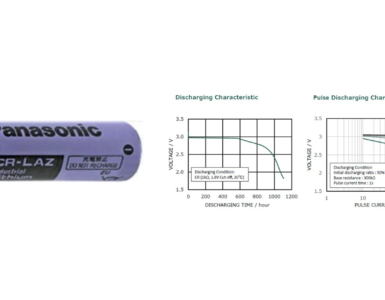

Electrochemical characterization was carried out using multilayer pouch cells constructed from the graphite and silicon anodes and a conventional NCM622 cathode. The cells had a capacity of 2.8 Ah.

Life tests – both at room temperature and at 45 °C – were used to examine the cycle stability of the various binder systems. In addition, the cells were subjected to a rate test with different charge and discharge rates as well as a storage test at 60°C over several weeks to test the temperature stability.

Customers benefit from many years of expertise in material development

Dr. Thorsten Habeck, Business Director Fiber Bonding Europe, Middle East & Africa of BASF SE.

We are pleased to be able to present our customers with valid data on the key performance indicators of our anode binders thanks to CUSTOMCELLS®

In the development of lithium-ion batteries, applications in niche markets in particular rely on rapid development and adaptation cycles. CUSTOMCELLLS® therefore enables customers to develop, prototype and mass produce high-quality lithium-ion battery cells in small to medium volumes on the basis of flexible manufacturing concepts and by using modern research and production facilities.

Building on many years of expertise in the field of material development, CUSTOMCELLLS® also enables its customers to evaluate not only binders, but also other electrode and cell components, such as current collectors, separators and conductive additives.

READ the latest Batteries News shaping the battery market

ORDER FOR BASF SUCCESSFULLY COMPLETED, November 16, 2021