Vulcan Energy successfully develops in-house lithium extraction technology: VULSORB™.

Vulcan Energy Resources Limited (Vulcan; ASX: VUL, FSE: VUL, the Company) has successfully developed, tested and demonstrated its own in-house lithium extraction sorbent, VULSORB™, for sustainable lithium extraction from the Upper Rhine Valley Brine Field and the Zero Carbon Lithium™ Project

Key Points

• VULSORB™ has demonstrated higher performance and lower water consumption for lithium extraction in Vulcan’s pilot plant, compared with commercially available sorbents tested by the Company. Test-work has been carried out on live brine from Vulcan’s commercially operating geothermal renewable energy plant, Natür3 lich Insheim.

• The manufacturing process for VULSORB™ has been shown to be environmentally benign, with many of the reagents recycled and with opportunities for Vulcan to use its own produced lithium to manufacture future sorbent once in production, thus further reducing Vulcan’s carbon footprint and operating costs while fulfilling the European Union’s circular economy goals.

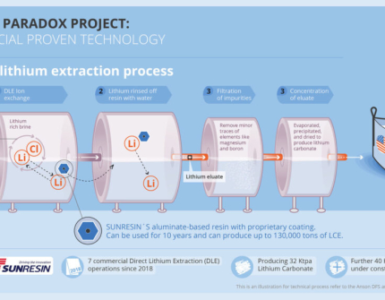

• VULSORB™ is a variation of the type of lithium extraction sorbents originally developed thirty years ago and used commercially around the world for lithium extraction from brine for the last 25 years. This Technology Readiness Level (TRL) 9 approach for lithium extraction can be used in most lithium-rich brines globally, provided salinity in the brine is high enough and there is sufficient heat to drive the process, with a brine pre-treatment step to increase sorbent durability which can be adjusted depending on local brine chemistry.

• The sorbent enables the lithium to be selectively extracted from the brine, providing a very pure lithium chloride eluate which can then be electro-chemically converted to lithium hydroxide for use in lithium-ion batteries in the European cathode, battery, and automaker industries. Vulcan has binding lithium hydroxide offtake agreements with Stellantis1, Volkswagen2, Renault3, LG

Energy Solution4 and Umicore5..

• This process is much faster and more efficient, with a lower carbon footprint, than the legacy industry method of using large-scale evaporation and large quantities of chemical reagents to extract the lithium and process into lithium hydroxide6.

. The sorbent extraction happens in hours, rather than up to 18 months7 as is the case with legacy extraction routes, allowing Vulcan to quickly respond to the needs of its customers.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

The main constituent of these sorbents is lithium chloride aluminate. These types of sorbents typically operate optimally at higher temperatures. In some commercial operations worldwide, Vulcan understands that gas is used to heat up the brine prior to lithium extraction.

8 In Vulcan’s case, the brine is naturally pre-heated from a hot geothermal reservoir, thereby reducing operating cost and removing the need for fossil fuels in the process, ultimately enabling a net zero carbon footprint for lithium production9

.

• Vulcan has selected VULSORB™ as its first choice of sorbent for lithium extraction in its planned Phase 1 commercial development, with first commercial production of lithium targeted for Q4 Vulcan continues to test other sorbents from commercial suppliers to provide further optionality, and for potential use in future phases of development.

• This further evidence of Vulcan’s developmental capability follows on from the announcement on

24 October 2022 of the highest grade, lowest impurity lithium hydroxide (LiOH) produced to date

from its pilot plant, which has been successfully operating for 19 months

Dr. Francis Wedin, Vulcan’s Managing Director and CEO said:

I congratulate Vulcan’s world renowned and highly experienced lithium extraction team on successfully developing, testing and demonstrating our own in-house lithium extraction sorbent, VULSORB™.

“In contrast to other developers who are increasingly using sorption in their developments10 but often outsourcing to external technology providers, Vulcan is uniquely positioned as both a lithium extraction technology provider, as well as a lithium chemicals and renewable energy developer.”

“Until now, there have been no commercially available sorbents for lithium extraction manufactured in Europe, thus making the region dependent on foreign supply chains. VULSORB™ will enable Europe to extract lithium from its own brine fields, without being exposed to geopolitical risk.”

“Vulcan will assess the potential of VULSORB™ to be used in other lithium brines in Europe and globally, particularly renewably-heated brines that can be used to extract lithium with net zero carbon footprint and zero fossil fuels, in line with Vulcan’s strict mandate to be carbon neutral.”

“The successful production of VULSORB™ together with the recent test results of the highest grade, lowest impurity lithium hydroxide to date from our pilot plant11, complement the continued works on our containerised Sorption Demonstration Plant and on our Phase 1 Definitive Feasibility Study (DFS), as our DFS nears conclusion in support of our target of first commercial production from our Zero Carbon Lithium™ Project in late 2025.”

About Vulcan

Founded in 2018, Vulcan’s unique Zero Carbon Lithium™ Project aims to decarbonise lithium production, through developing the world’s first carbon neutral, zero fossil fuels business, with the co-production of renewable geothermal energy on a mass scale.

By adapting existing technologies to efficiently extract lithium from geothermal brine, Vulcan is aiming to deliver a local source of sustainable lithium for Europe, built around a net zero carbon strategy with a strict exclusion of fossil fuels. Already an operational renewable energy producer, Vulcan will also provide renewable electricity and heat to local communities.

Vulcan’s combined geothermal energy and lithium resource is the largest in Europe, with license areas in the Upper Rhine Valley, Germany, and in Italy. Strategically placed in the heart of the European electric vehicle market to decarbonise the supply chain, Vulcan is rapidly advancing the Zero Carbon Lithium™ Project to ensure timely market entry, with the ability to expand to meet the unprecedented demand that is building in the European markets.

Guided by our Values of Integrity, Leadership, Future-focused and Sustainability, and united by a passion for environmentalism and leveraging scientific solutions, Vulcan has a unique, world-leading scientific and commercial team in the fields of lithium chemicals and geothermal renewable energy.

Vulcan is committed to partnering with organisations who share its decarbonisation ambitions and has binding lithium offtake agreements with some of the largest cathode, battery and automakers in the world.

As a motivated disruptor, Vulcan will leverage its expert multidisciplinary team, leading geothermal technology and position in the European EV supply chain to be global leaders in the production of zero fossil fuel, carbon neutral lithium, while being nature positive.

Vulcan aims to be the largest, most preferred, strategic supplier of lithium chemicals and renewable power and heating from Europe, for Europe; to empower a net zero carbon future.

Vulcan successfully develops in-house lithium extraction technology: VULSORB™, November 14, 2022