Unifrax announces large-scale silicon fiber anode, SiFAB, manufacturing line.

Unifrax, a Buffalo, New York headquartered global manufacturer of high-performance specialty materials, announced plans to build its first large-scale SiFAB (silicon fiber anode material) manufacturing line at its north central Indiana facility that could add up to 74 new jobs by the end of 2023.

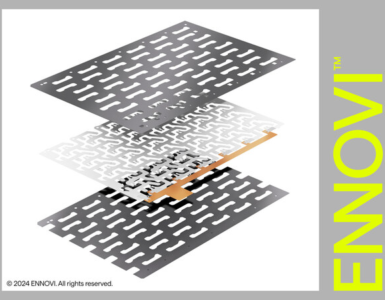

SiFAB is a proprietary silicon anode battery technology which enables significantly greater energy density in lithium-ion battery systems than prevailing technologies. SiFAB is currently in advanced testing and has shown promising performance in multiple battery systems.

The anode technology has successfully been tested with incremental Si loadings of greater than 40%. Along with greater energy density, SiFAB is expected to provide faster charges and longer battery life for applications including electric vehicles, portable electronics, power tools, energy grid storage and aerospace.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Unifrax is uniquely positioned to meet customer demand and develop SiFAB at scale, due to its existing manufacturing plant and infrastructure in New Carlisle. The Indiana plant will be the first to begin building SiFAB long-term manufacturing capacity.

The new line is slated to create up to 20 new jobs by the end 2022, with additional growth anticipated by the end of 2023. Unifrax will have more information on open positions later this year on its website.

John Dandolph, president and CEO, Unifrax.

SiFAB is the latest development using fiber-based technology to create step change value for customers.

“This transformational material represents another addition to our robust electric vehicle and battery solutions portfolio.”

“Unifrax is a large, global manufacturing company introducing game changing advanced silicon anode materials that can be used in existing manufacturing processes. Our track record and proven ability to develop new and unique technologies will help transform the battery industry with SiFAB.”

“The ability to leverage our existing facility and add new infrastructure to support SiFAB manufacturing in New Carlisle will significantly accelerate the timeline for supplying this critical material to our partners. We are appreciative of the ongoing partnership between the state of Indiana and St. Joseph County as we leverage the footprint of our existing facility to bring new jobs and opportunities to the region.”

Chad Cannan, senior vice president of research and development, Unifrax.

We designed SiFAB from its inception to be manufactured at large scale so that we could supply all market segments (EV’s, consumer electronics, power tools, and renewable storage), utilize our existing global manufacturing footprint, and deliver a product that has a high degree of quality and consistency.

READ the latest Batteries News shaping the battery market

The Indiana Economic Development Corporation offered Unifrax up to $1.1 million in conditional tax credits based on the company’s job creation plans. These tax credits are performance-based, meaning the company is eligible to claim incentives once Hoosiers are hired. St. Joseph County has also confirmed $775K in county tax incentives.

Jim Staton, interim secretary of commerce for the state of Indiana.

Indiana is a leader in manufacturing, with the highest concentration of manufacturing jobs in the nation supported by 9,000 facilities across the state.

“As new trends and technologies change the state of today’s manufacturing industry, Indiana is focused on partnering with forward-thinking companies like Unifrax to propel long-term growth in manufacturing and create quality career opportunities for Hoosiers.”

Andrew Kostielney, St. Joseph County Commissioner also added:

The recent announcement by Unifrax is exciting news, not just for St. Joseph County, but for the entire region.

“Unifrax has long been an important manufacturing leader in the area, and this expansion indicates their commitment to our county for decades to come. Their new SiFAB line will not just create new jobs, it will also showcase the importance of green, sustainable technology.”

After more than 75 years of experience in fiber-based technology and manufacturing, Unifrax is taking its first step into developing silicon fiber for the lithium-ion battery manufacturing market.

With a decades-long track record of developing and supplying engineered inorganic materials at a large scale to advanced industries worldwide including electric vehicles, aerospace and chemical processing, Unifrax recently debuted two new fiber-based catalysis offerings for the automotive and industrial markets – Eco-lytic™ and FlexCat™.

To learn more about SiFAB, and to request a sample, Unifrax launched a new website introducing SiFAB with technical, manufacturing and application specific information.

- Backed by Clearlake Capital, Unifrax to manufacture SiFAB technology at New Carlisle facility, adding up to 74 new jobs

Unifrax Announces SiFAB™ Manufacturing Line, NEW CARLISLE, Ind. & BUFFALO, N.Y., June 15, 2021