Talga silicon anode demand drives progress – Talnode®-Si silicon anode achieves Tier-1 automotive and battery customer targets in qualification tests to date.

Battery company Talga Group Ltd (“Talga” or “the Company”) (ASX:TLG) is pleased to provide an update on commercialisation and customer qualification of Talnode®-Si, the Company’s proprietary silicon anode product for lithium-ion (Li-ion) batteries.

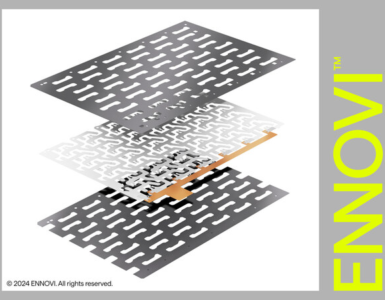

Talnode®-Si is a composite of graphite, graphene and ~50% silicon designed to significantly boost battery energy capacity when blended into existing commercial graphite anode materials. Talga has been developing Talnode®-Si since 2018 (ASX:TLG 24 October 2018) at its facilities in

Cambridge, UK, with commercial samples being produced at its pilot facility in Rudolstadt, Germany.

Recent qualification and pilot trials completed with a global EV manufacturer confirmed Talnode®-Si performance under commercial cell manufacturing conditions. Li-ion battery cells containing 9% Talnode®-Si, manufactured in battery tolling and in-house development facilities, boosted battery energy capacity by ~40%. Test results of first cycle efficiency and 500 cycle life to date exceed customer targets at this stage of development.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Following positive customer tests and feedback, in accordance with its commercial strategy Talga is expanding its existing pilot line in Rudolstadt, Germany, to produce greater quantities of Talnode®-Si for commercial qualification. Commissioning of the expanded pilot line is to be completed in Q1 2023.

In parallel, the Company is conducting feasibility work towards accelerating commercial Talnode®-Si production options. Negotiations with leading global EV manufacturers regarding supply volumes has commenced and production site location selection in Europe is well underway.

Background and Talnode®-Si Development

In theory, a pure silicon anode is capable of providing ~10x the capacity of standard graphite anode in a Li-ion battery. However, in practice silicon swells and cracks during charging, shortening battery life. Additionally the production cost is significantly higher than graphite due to more expensive materials and higher cost process technologies.

Talga combines low-cost European sources of silicon with its highly engineered graphene and graphite materials to produce its ‘drop-in’ silicon anode additive product Talnode®-Si. The proprietary production process and graphene technology helps reduce silicon expansion during charging, and the approach offers large scale industrial production potential and lower costs compared to other known silicon anode technologies.

Tests by a global Tier-1 EV manufacturer of unblended Talnode®-Si has demonstrated ~5x the energy capacity of graphite-only commercial anodes (1,800mAh/g vs 360mAh/g).

Mark Thompson, Talga Managing Director, commented:

We are very pleased with the rapid advancements across Talnode®-Si customer qualification and scaleup.

“The commercialisation of our silicon-graphene composite will complement our flagship Talnode®-C graphite anode product and diversify Talga’s business growth.”

Applications and Market

Silicon anodes help increase the performance of a variety of battery chemistries, from lithium iron phosphate (LFP) to NMC / NCA type. In an EV, depending on the vehicle, a 10% addition of silicon to the battery anode can translate into an additional ~15% range over traditional Li-ion batteries.

Alternatively, silicon-boosted batteries can be made smaller or lighter, providing benefits for not only EV’s but demanding applications such as electric aviation, race cars, marine craft and drones. Talga notes significant and rising market interest in scaling production for silicon anode outside China by global OEMs and battery makers.

Benchmark Mineral Intelligence forecast the 2030 anode market share for silicon anode to be 5% or around 150,000tpa. Authorised for release by the Board of Directors of Talga Group Ltd.

About Talga

Talga Group Ltd (ASX:TLG) is building a European battery and advanced materials supply chain to offer products critical to its customers’ innovation and the shift towards a more sustainable world. Vertical integration, including ownership of high-grade Swedish graphite projects, provides security of supply and creates long-lasting value for stakeholders. Website: www.talgagroup.com

Highlights:

• Talnode®-Si silicon anode achieves Tier-1 automotive and battery customer targets in

qualification tests to date

• Customer tests show significant boosts in Li-ion battery energy capacity using Talnode®-Si

• German pilot plant to be expanded Q1 2023 and commercial production options advanced

• Commercial negotiations with Tier-1 EV and battery manufacturers commenced.

READ the latest Batteries News shaping the battery market

Talga silicon anode demand drives progress, December 14, 2022