Study: Nth Cycle critical mineral refining and recycling technology verifies 92% reduction in refining emissions.

Nth Cycle, the innovative metal refining technology company, announced independent verification of its low-emissions refining technology, called electro-extraction.

According to the independent study, the Boston-area company offers refining capabilities that are 92% lower emissions than traditional mining and refining processes and 44% lower emissions than more modern critical minerals recycling technologies.

Megan O’Connor, co-founder and CEO of Nth Cycle, said:

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

With the passing of the Inflation Reduction Act, there’s now a growing gap between supply and the extraordinary demand for critical minerals to build lithium ion batteries.

“We cannot rely on emissions-intensive refining processes from overseas vendors to meet our demands. This independent validation proves our ability to create a sustainable path to a sustainable planet right here at home.”

Nth Cycle’s first product is a mixed hydroxide precipitate (“MHP”), which contains nickel and cobalt. Production of MHP through laterite ore refining is growing in popularity as a precursor chemical for battery cathode manufacturers.

However, 81% of today’s MHP supply is refined in Indonesia, by Chinese companies, through a carbon-intensive hydrometallurgy refining process called HPAL (high pressure acid leaching).

This HPAL-based supply of MHP is harmful to the environment and as a foreign supply, is not a compliant supply of critical minerals for domestic battery manufacturing under the recently passed Inflation Reduction Act.

With this independent verification, Nth Cycle customers can have confidence in a domestic supply of MHP that meets compliance standards for EV tax credits under the Inflation Reduction Act while dramatically reducing the carbon footprint of domestic refining.

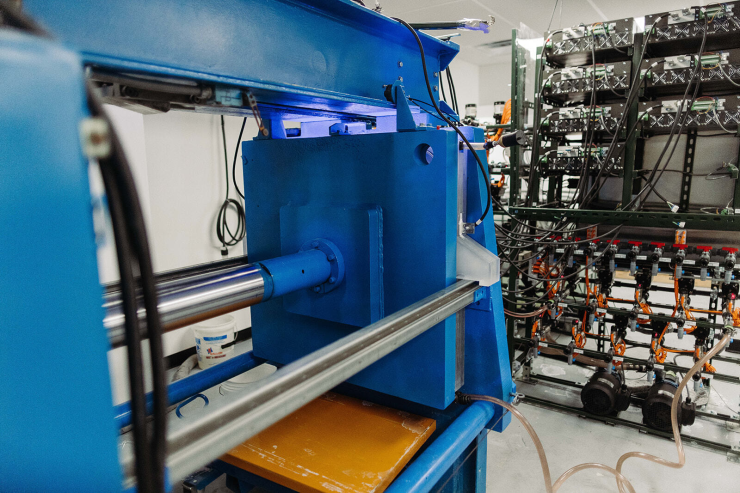

Nth Cycle’s unique, modular electro-extraction technology supports refiners, miners and battery recyclers as an alternative or enhancement to older, emissions-intensive hydrometallurgical and pyrometallurgical processes.

Nth Cycle’s technology transforms the outputs of metal scrap, electronics recycling, untapped mining resources, and waste from existing mines into high-purity critical minerals ready to be used in new production.

Nth Cycle is hiring and has open positions in engineering, business, and the sciences.

For more information, visit: https://nthcycle.com/careers/

About Nth Cycle

Nth Cycle is a metal processing technology company that works with recyclers and miners. We are the heart of metals processing – the crucial step that profitably separates critical minerals from other elements, transforming them into production-grade feedstocks for the energy transition.

At Nth Cycle, we believe all the critical minerals needed for the energy transition are already in circulation. We just didn’t have a clean, profitable way of retrieving them, until now.

READ the latest Batteries News shaping the battery market

Study: Nth Cycle’s Critical Mineral Refining and Recycling Technology Verifies 92% Reduction in Refining Emissions, BOSTON, October 20, 2022