Pilbara Minerals and Calix Limited announce investment to build and operate plant for electric calcination for high-purity lithium-rich chemical salt.

Australian lithium producer, Pilbara Minerals Limited (Pilbara Minerals – ASX: PLS) and Australian environmental technology company, Calix Limited (Calix – ASX:CXL), announce that their respective Boards have made a final investment decision to construct and operate a Mid-Stream Demonstration Plant in a joint venture.

The Project aims to demonstrate the potential to reduce carbon emissions intensity for the hard-rock lithium supply chain via the creation of a high-purity lithium-rich chemical salt (Mid-Stream Product or lithium phosphate) using electric calcination that could be powered from renewable energy when available.

Market engagement with participants in the battery and chemicals supply chain has encouraged the pursuit of the Mid-Stream Product and confirmed that it has strong potential to be an improved lithium feedstock for the lithium chemicals industry.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

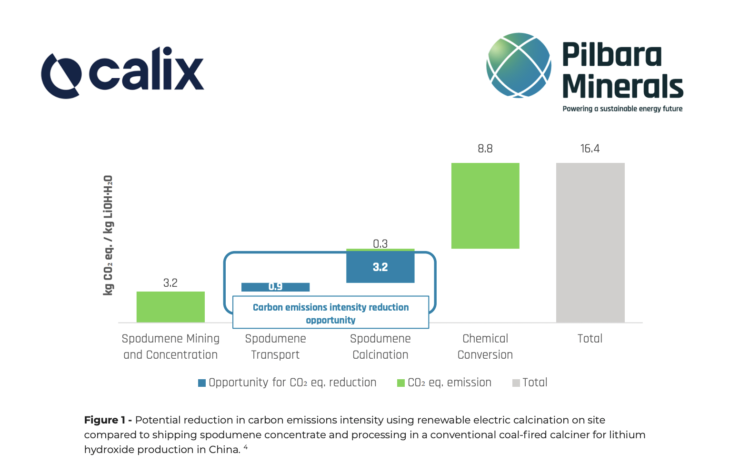

Life Cycle Assessment studies commissioned by Pilbara Minerals have calculated that when using 100% renewable electricity for electric calcination, the carbon emissions intensity of spodumene calcination can be reduced by more than 90% when compared to using coal as the primary source of thermal energy in rotary kiln calcination, and by more than 80% when compared to the use of natural gas.4

The assessments conclude that successful implementation of electric calcination on-site at a spodumene mine and concentrator could materially reduce carbon emissions intensity associated with spodumene calcination by more than 3 kg CO2 eq. per kg LiOHᐧH₂O when using renewable energy compared to using coal as the thermal energy source in rotary kiln calcination (refer Figure 1).

Potential reductions in carbon emissions are also anticipated from producing a Mid-stream

Product by avoiding the transport of waste associated with spodumene concentrate.

As well as reducing calcination carbon emissions intensity which is one of the most energy intensive steps in the lithium battery materials supply chain, the Project also aims to enable greater value extraction from hard-rock lithium assets, by allowing spodumene producers to better utilise mineral resources and move down the battery materials value chain by producing a higher-value intermediate product on-site.

This will potentially enable more value to be captured onshore at the resource.

The strategy of producing a mid-stream product also has the potential to unlock remote hard-rock assets globally that have challenges such as long distances to export infrastructure or customers.

Key Objectives

Key objectives of the Project include:

- to validate Calix’s electric flash calciner in converting spodumene concentrate from α to β phase.

- to validate calcination of lower grade fine spodumene concentrate which could potentially lead to improved overall lithia recoveries in the spodumene concentrator plant.

- to validate the potential to use electric flash calcination – capable of being powered by 100% renewable energy when available – to reduce CO2 equivalent emissions intensity in spodumene calcination by >80% when compared to conventional fossil fuel-fired rotary kilns.

- to generate supporting data to confirm lower capital and operating costs over conventional calcining processes, by utilising electric calcining

- to demonstrate an ability to produce a lithium-rich mid-stream product on-site, which significantly reduces the transportation of waste from site and potentially enables more “value adding” at the resource.

- to enhance Pilbara Minerals’ operational learnings in chemical processing which will be readily transferable at a commercial scale.

- to produce sufficient volumes of Mid-Stream Product to test market pricing.

To date the JV has been informed at a pilot scale from prior test work that was undertaken in the lead up to making a FID. The Project will now seek to achieve these outcomes at a demonstration scale using a commercial-scale calciner.

Emissions Intensity

Installing a chemical plant at site will increase Pilbara Minerals’ Scope 1 and 2 emissions by undertaking additional processing within its operational footprint that would otherwise be expected to be captured as downstream Scope 3 emissions.5

The Project seeks to demonstrate that electric calcination of spodumene has a lower carbon footprint than conventional coal or gas fired rotary calcination, when powered by renewable energy, and that a more lithium enriched product can be produced on site with less transportation of waste than conventional processing.

The Project aims to demonstrate that the technology, when commercialised, has the potential to reduce aggregate Scope 1, 2 and 3 emissions across the hard rock lithium supply chain in comparison to conventional rotary calcination.

Project Parameters

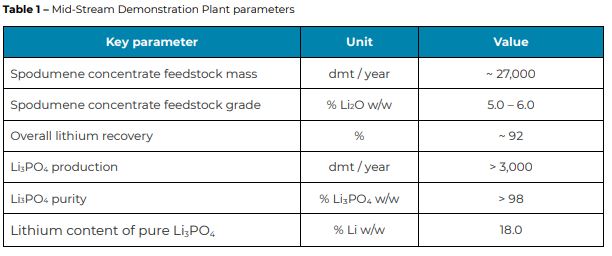

The Project at full production capacity is estimated to produce more than 3,000 tonnes per year of lithium phosphate (Li3PO4). The key processing and production parameters for the Project are detailed below (refer Table 1).

The Calix electric calciner designed for the Project represents a commercial-scale single tube kiln. Deployment of this technology in a commercial-scale chemical train will comprise multiple units of a comparable scale.

Spodumene concentrate feed will be purchased by the JV from Pilbara Minerals on commercial terms consistent with market pricing.

Pilbara Minerals as manager of the JV will seek to sell all lithium phosphate produced from the Demonstration Plant on commercial terms to participants in the lithium supply chain through ongoing market engagement which to date has shown strong support for the product.

A schematic of the Project is detailed below (refer Figure 2)

Project Construction Costs

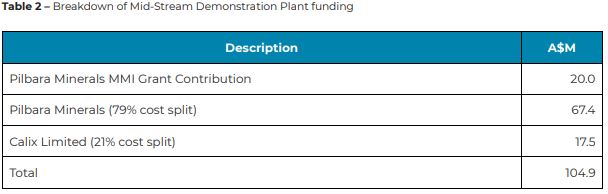

Budgeted construction costs of the Project of up to $104.9M will now be funded by the parties pursuant to a revised construction cost split of 79%:21% (Pilbara Minerals: Calix), with the Australian Government contributing A$20M received under the Modern Manufacturing Initiative (MMI) grant signed on 28 April 20236.

Pilbara Minerals and Calix had previously agreed a 65%:35% construction cost split with the royalty free use of Calix’s calciner technology for the Project on an exclusive basis being recognised as a 10% in-kind contribution on the budgeted construction costs.

7 The parties have since agreed to alter the cost split in recognition of the revised construction cost of the calciner and other elements of the Demonstration Plant, and in exchange for revising the terms of the royalty rate payable if Pilbara Minerals adopts the electric calcination technology for a mid-stream plant at Pilgangoora or for future commercial plants, including with joint venture partners.

The revised net royalty payable by Pilbara Minerals in the event of commercial scale adoption would be based on a percentage of FOB revenue, at a rate consistent with a standard licence or royalty on the net benefit of the technology and is commercial in confidence.

Any additional capital costs above budgeted expenditure of $104.9M will be funded by the parties in accordance with their participating interests in the JV at 55%:45% (Pilbara Minerals: Calix) which remain unchanged.

All other terms and conditions of the JV remain as summarised in the ASX release dated 28 November 2022. The funding breakdown for the project is detailed below (refer Table 2).

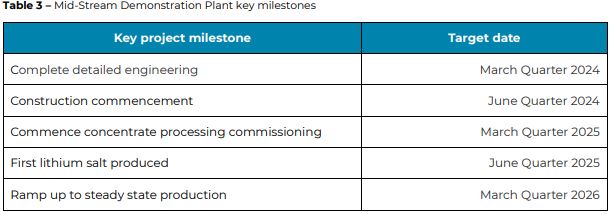

A project contingency of $11.7M has been allowed for on budgeted construction costs. Next steps and timelines The key target milestones related to the successful completion and operation of the Project are listed below (refer Table 3)

Following successful commissioning and upon achieving steady state production, it is anticipated that an assessment over a 12 to 18 month period should determine the technical and commercial performance of the technology.

Commercialisation

Should the calcination technology be successfully demonstrated, Pilbara Minerals has the right to licence the technology from the JV for use in its own potential mid-stream or downstream commercial scale plants to produce lithium salts or chemicals, either at Pilgangoora or in respect of future projects that Pilbara Minerals may develop either alone or in partnership.8

The parties to the JV may also seek to commercialise the technology through an incorporated joint venture having the exclusive worldwide right to licence the technology to third parties in respect of lithium processing applications. This may lead to additional revenues for the JV and its parties.

Dale Henderson, Pilbara Minerals’ Managing Director and CEO said:

Following further studies and pilot test work, we are delighted to be taking the next step in our mid-stream strategy with the construction and operation of a Mid-Stream Demonstration Plant with our JV partner Calix.

“The mid-stream strategy has potential to materially improve the battery materials supply chain for lithium through reduction in carbon energy intensity, reduction in transport volumes and creating more value at the mine site. It has the potential to be a game changer compared to the traditional spodumene to chemicals processing route.”

“The demonstration plant with Calix is an important step to further the development of the technology with the aim of commercialising the technology for application at the Pilgangoora operation and across the lithium industry through our commercialisation JV with Calix. This could in time open up an additional revenue stream for the Company.”

“I would like to acknowledge the financial contribution of the Australian Government to the demonstration plant project through a $20M Modern Manufacturing Initiative Grant.”

“It’s great to see the Australian Government supporting Australian innovation in the critical

minerals industry.”

Calix CEO and Managing Director, Phil Hodgson said:

We are delighted that the Project has passed the FID milestone.

“Together with Pilbara Minerals, we look forward to demonstrating the potential of our electric calcination technology to dramatically reduce the carbon footprint of Australian lithium. The success of the joint venture will also showcase the opportunity of combining Australian mineral and renewable energy resources with innovative Australian technology to enable the reliable and sustainable supply of value-added critical minerals to the world.”

KEY POINTS

- Final Investment Decision (FID) has been made to progress the construction and operation of a Mid-Stream Demonstration Plant (the Project) at the Pilgangoora Operation in joint venture (JV) between Pilbara Minerals Limited and Calix Limited. 1

- The Project aims to demonstrate the benefits of producing a mid-stream lithium enriched product using Calix’s patented electric kiln technology which has the potential to reduce hard-rock lithium processing carbon emission intensity if powered by renewable energy.

- Independent Life Cycle Assessment studies estimate that converting spodumene using electric calcination when using 100% renewable energy has the potential to reduce calcination carbon emissions intensity by >80%2 , which would materially reduce carbon emissions in one of the most energy intensive steps of the lithium battery materials production process.

- Delivering a more lithium-enriched mid-stream product has the potential for industry wide benefits including reduced transport of waste, greater value creation and utilisation of the mineral resource and unlocking future assets with limited transport infrastructure.

- Estimated construction costs of $104.9M will be partially funded with a $20M Australian Government grant3 with Pilbara Minerals now funding $67.4M of the remaining budgeted construction expenditure

- Pilbara Minerals as manager of the JV will manage both the construction and operational phases of the Project.

- Successful demonstration of the Project may lead to future commercialisation of the technology. Pilbara Minerals has the right to a licence to use the electric calcination technology for use in its own mid-stream or downstream commercial scale plants potentially developed either at Pilgangoora or in other locations including in joint venture with third parties.

Highlights:

- Board approval granted for construction of demonstration plant to produce value added lithium product at pilgangoora.

- Project seeks to demonstrate potential to improve the battery materials supply chain through decarbonisation of spodumene processing, reduction in transport volumes and increased value-add processing at the mine site.

FINAL INVESTMENT DECISION FOR MID-STREAM DEMONSTRATION PLANT, August 2, 2023