Panasonic accelerates Net Zero ambitions with RE100 demonstration facility in Wales in 2024 – hydrogen fuel cells, solar PV and battery storage.

Panasonic Corporation (hereinafter referred to as “Panasonic”) has today announced its intention to make a significant investment in one of its UK manufacturing facilities as part of its commitment to accelerate decarbonisation. This investment will enable the launch of an RE100 demonstration production facility at Panasonic Manufacturing UK Ltd. (hereinafter referred to as “PMUK”), in Cardiff, Wales in 2024. Over the next two years, Panasonic will invest approximately 130 million Euros to further develop the core technology in Japan and launch this pilot in Cardiff plus another location in Europe later next year.

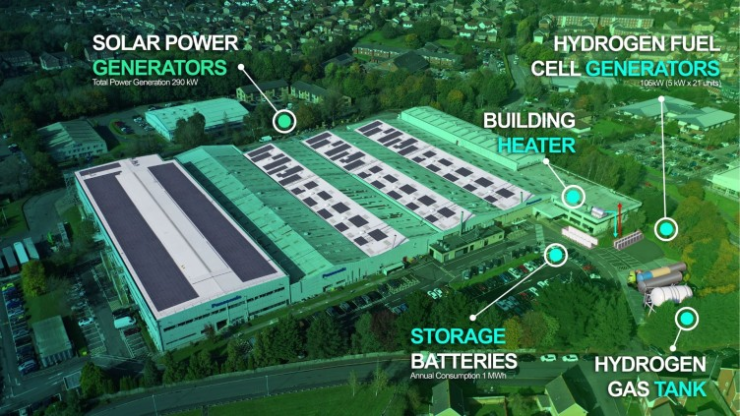

Subject to planning consent, the investment will enable the retrofit of the Welsh Panasonic factory with an integrated power supply and demand management solution that uses a combination of pure hydrogen fuel cells, solar PV and battery storage. The over-arching goal of this investment is to prove that 100% of the electricity consumed at this site can be powered entirely by renewable sources (a combination of solar and hydrogen).

This planned investment is aligned to Panasonic’s long-term environmental vision, Panasonic GREEN IMPACT, which defines ambitious commitments to address climate change and contribute to a more sustainable future. In 2019, Panasonic became a member of RE100 which is a global initiative that brings together the world’s most influential businesses to accelerate change towards zero carbon grids at scale. A key outcome of Panasonic’s RE100 membership is a commitment to source 100% of its energy from renewable sources by 2050[1].

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

As part its Panasonic GREEN IMPACT initiative, the company is currently engaged in a number of activities that contribute towards reducing CO2 emissions from its own operations to virtually Net-Zero by 2030. Ultimately, this will contribute to a total of 110 million tons of own emission impact and reduction. These own reductions are just around one third of Panasonic’s total goal of reducing and avoiding over 300 million tons[2] by 2050, which accounts for about 1% of the current total global emissions of 33 billion tons3.

Integrated energy solution

The Cardiff project will see Panasonic Manufacturing UK achieve a high degree of energy resilience through an integrated energy solution that combines 21 of its own pure hydrogen fuel cell generators (with a total output of 105 kW), photovoltaic panels (290 kW) and battery storage (1 MWh). Panasonic says it also plans to use its learnings from its RE100 demonstration facilities in Japan[1] and the UK to support its customers in meeting their own Net Zero ambitions. The different climate conditions in its demonstration projects in the UK and Japan will enable Panasonic to customise its solution according to local requirements.

‘Beacon project’

The Panasonic production facility in Cardiff manufactures around 250,000 microwave ovens and small appliances a year. Panasonic selected this factory as a RE100 demonstration site because it has the potential to be an inspirational ‘beacon project’ for sustainable manufacturing. It will also offer proof that it is possible to retrofit older industrial buildings with leading-edge renewable energy technologies.

Panasonic will share its learnings and transferable best practice from its experiences at Cardiff with its customers and other sustainability-conscious local businesses. The company also aims to use its RE100 solution facility to inspire younger generations. As such, Panasonic has plans to invite university students and school pupils to the factory.

Hydrogen fuel cell technology

Panasonic’s RE100 solution uses its own 5kW pure hydrogen fuel cell generators. Manufactured in Japan, up to 250 fuel cell units can be connected depending on power demand and location. By integrating an energy management system and a storage battery, it will be possible for the Panasonic factory to manage its fluctuations in power demand and renewable energy production.

Once operational, Panasonic’s RE100 solution at its Cardiff factory will deliver wide-ranging operational and sustainability benefits. Significantly, it will help to reduce excess and wasted electricity and heat energy whilst simultaneously ensuring a stable supply of renewable power. In addition, this decentralised approach to demand management also increases the company’s energy resilience in a volatile market.

Integrated energy solution

The Cardiff project will see Panasonic Manufacturing UK achieve a high degree of energy resilience through an integrated energy solution that combines 21 of its own pure hydrogen fuel cell generators (with a total output of 105 kW), photovoltaic panels (290 kW) and battery storage (1 MWh). Panasonic says it also plans to use its learnings from its RE100 demonstration facilities in Japan[1] and the UK to support its customers in meeting their own Net Zero ambitions. The different climate conditions in its demonstration projects in the UK and Japan will enable Panasonic to customise its solution according to local requirements.

‘Beacon project’

The Panasonic production facility in Cardiff manufactures around 250,000 microwave ovens and small appliances a year. Panasonic selected this factory as a RE100 demonstration site because it has the potential to be an inspirational ‘beacon project’ for sustainable manufacturing. It will also offer proof that it is possible to retrofit older industrial buildings with leading-edge renewable energy technologies.

Panasonic will share its learnings and transferable best practice from its experiences at Cardiff with its customers and other sustainability-conscious local businesses. The company also aims to use its RE100 solution facility to inspire younger generations. As such, Panasonic has plans to invite university students and school pupils to the factory.

Hydrogen fuel cell technology

Panasonic’s RE100 solution uses its own 5kW pure hydrogen fuel cell generators. Manufactured in Japan, up to 250 fuel cell units can be connected depending on power demand and location. By integrating an energy management system and a storage battery, it will be possible for the Panasonic factory to manage its fluctuations in power demand and renewable energy production.

Once operational, Panasonic’s RE100 solution at its Cardiff factory will deliver wide-ranging operational and sustainability benefits. Significantly, it will help to reduce excess and wasted electricity and heat energy whilst simultaneously ensuring a stable supply of renewable power. In addition, this decentralised approach to demand management also increases the company’s energy resilience in a volatile market.

In addition to an energy management system for the total application, Panasonic’s 5 kW pure hydrogen fuel cell generators have another energy management control software according to fluctuations in power demand. The software enables balanced running time among the 21 hydrogen fuel cells to extend the lifetime of each and to enable uninterrupted maintenance during operation.

Energy efficiency benefits

The heat generated during hydrogen power generation can be used to heat spaces and domestic hot water, further improving overall energy efficiency. By demonstrating the RE100 solution at its factory in Wales, Panasonic aims to develop a solution that is optimised for local conditions.

Commenting on the demonstration of the RE100 solution in the UK,

Lord Dominic Johnson of Lainston CBE, UK Minister for Investment, stated:

I am thrilled to welcome Panasonic’s significant investment into Wales, marking a momentous occasion for the United Kingdom and Panasonic.

“This is great news for our nation, and I would like to extend our heartfelt thanks to Panasonic for their ongoing commitment to the UK. The clean energy transition is not only vital for our environment but is a key part of our economic strategy. We stand ready and eager to work closely with Panasonic, supporting them in expanding similar projects across the UK. Together, we will continue to innovate, grow, and contribute to a greener future for all.”

Vaughan Gething, Welsh Government Minister for the Economy, said:

For decades, Wales has invested in strong partnerships with Japanese businesses, and I want to extend my sincere thanks to Panasonic for cementing their ongoing commitment to the workforce in Cardiff and to the wider Welsh economy.

“I’m delighted Panasonic continue to invest in Wales and our shared ambitions for strong economic growth. Not only are they bringing innovative, groundbreaking technology to the Welsh capital but also supporting the Welsh Government’s journey to net zero by 2050. Meeting those targets requires active industrial policy and a commitment to partners, such as Panasonic. This is how we can deliver the technologies, infrastructure and projects that bring about a stronger, fairer, and greener Wales.”

Masahiro Shinada, CEO of Panasonic, stated:

With a mission to contribute to the wellbeing of people, society and the planet, Panasonic takes a medium- to long-term view of its business, aiming to create a society that achieves both wellbeing and sustainability.

“By demonstrating the RE100 solution at our factory in the UK, we hope to create a new business that contributes to UK society and the fight against climate change. In addition, we aim to develop our business in the long term to achieve a hydrogen society and carbon neutrality”

Robert Blowers, Managing Director of Panasonic Manufacturing UK Ltd commented:

Everyone in our business feels energised and excited that our Cardiff factory has the potential to become a beacon for sustainable manufacturing.

“This is such an important project – both for Wales, for the UK and wider society. It will be a shining example of what can be achieved by the integration of cutting-edge technologies and innovative approaches to accelerating the energy transition. On a personal level, I am extremely proud of everything that we are doing through our Panasonic GREEN IMPACT pledge to deliver a major shift in how we achieve and support the UK and Wales’s net zero ambitions as well as our own carbon neutrality.”

Demonstration of RE100 solution at PMUK

Demonstration site

Microwave oven manufacturing factory

• Peak power: Approx. 280 kW

• Annual power consumption: Approx. 1 GWh

• Factory building area: 22,000 m2

Project launch: 2024

Demonstration facility

• Pure hydrogen fuel cell generators: 105 kW (21 units)

• Photovoltaic generators: 290 kW

• Storage batteries: 1 MWh

Verification details

• Integrated control of power generators and a storage battery system optimised for UK weather and power demand conditions, as well as factory power demand fluctuations

• Improvement of energy efficiency by using the heat generated by pure hydrogen fuel cell generators (for heating air and water)

<Panasonic Group’s environmental efforts>

The Panasonic Group has adopted the long-term environmental vision, Panasonic GREEN IMPACT (PGI), to achieve both the wellbeing of people and society as well as a sustainable global environment. It is engaged in various activities toward reducing CO2 emissions from its own operations to virtually net-zero by 2030 and to contribute to a total of 300 million tons2, or more in avoided emissions by 2050, about 1% of the current total global emissions of 33 billion tons3.

2: Based on 2020 CO2 emission factors.

3: CO2 emissions from energy reached 33.6 billion tons in 2019, according to the IEA.

READ the latest Batteries News shaping the battery market

Panasonic accelerates Net Zero ambitions with RE100 demonstration facility in Wales in 2024 – hydrogen fuel cells, solar PV and battery storage. source