Morrow Batteries and Haldor Topsoe sign binding supply agreement for pilot production of cobalt-free material.

Morrow Batteries has signed a binding supply agreement with the Danish technology provider Haldor Topsoe. The agreement ensures Morrow exclusive access to a significant share of the pilot production volumes of Topsoe’s world leading lithium-nickel-manganese oxide (LNMO) materials.

Terje Andersen, CEO of Morrow Batteries.

We are delighted to partner with Haldor Topsoe on the supply of advanced cobalt-free LNMO cathode materials.

“The agreement ensures that we have the cathode material needed to qualify lithium-ion batteries based on LNMO technology with our customers.”

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

The agreement will give Morrow access to up to 150 tonnes of LNMO cathode materials annually, to develop battery cell chemistries based on this innovative material towards industrialization.

Over the past 10 years, Haldor Topsoe has invested significant resources in research and development of cathode active materials for cobalt-free lithium-nickel-manganese oxide (LNMO)-battery cells. The company’s world-leading technology can reduce the cost of battery cells by 25 percent compared to the current level.

Roeland Baan, CEO of Haldor Topsoe A/S.

The development of rechargeable batteries, that are both cost effective and utilize resources more efficiently, is a necessary step for increased electrification.

“We are very pleased to sign this supply agreement with Morrow Batteries and that our cathode technology will be deployed in the market.”

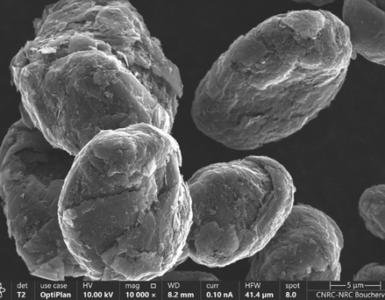

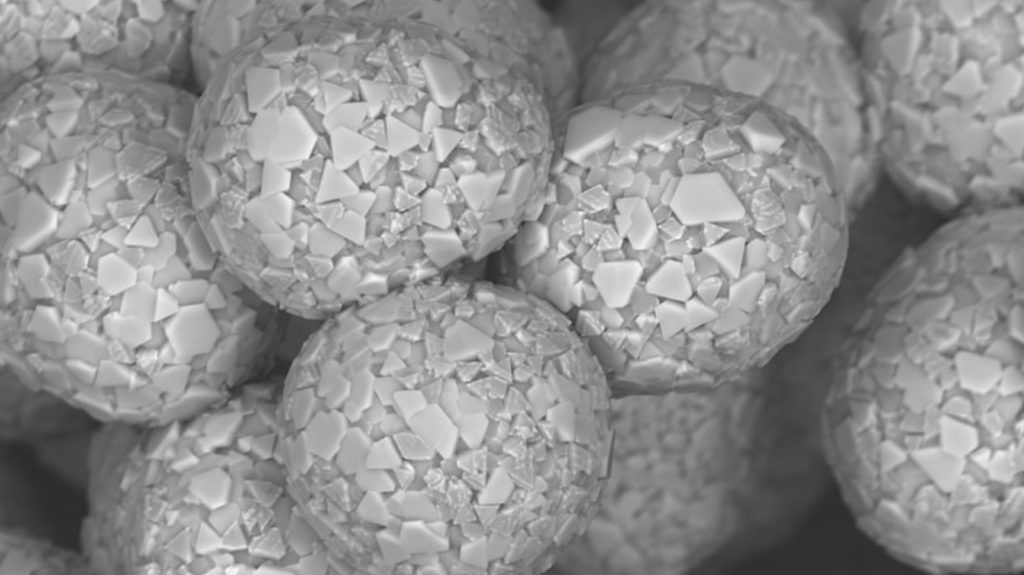

The new cathode active material technology draws on Haldor Topsoe’s know-how from many years of in-depth experience with catalysis and materials science, from product development at the nanoscale to fully industrialized manufacturing at the ton-scale.

(Image of LNMO-particles. Photo: Haldor Topsoe)

Morrow’s LNMO battery cells based on this material have several advantages. The working potential is 25% higher than commercial high-nickel cathodes, enabling fewer cells in applications such as power tools and electric vehicles, whilst the three-dimensional spinel structure makes it possible to achieve high discharge rates and fast battery charging.

The absence of cobalt and the relatively low nickel content make this a cost-effective alternative to today’s mainstream lithium-ion battery chemistries.

READ the latest Batteries News shaping the battery market

Morrow and Haldor Topsoe sign binding supply agreement for pilot production of cobalt-free material, December 22, 2021