Germany – sustainable batteries based on calcium and sulfur.

Our society is becoming increasingly electrified – and electrochemical energy storage in the form of batteries is playing a central role in providing the energy we need. At the same time, however, demands are increasing with regard to the sustainability and safety of the battery materials used.

In September 2022, the joint project “CaSino” therefore started to determine the potential of the so-called calcium-sulfur (Ca-S) battery as an alternative to lithium-ion batteries.

The project consortium consists of five research institutions, two industrial companies and an industrial advisory board and is coordinated by DLR Stuttgart. It is being funded by the German Federal Ministry of Education and Research (BMBF) with 3 million euros as part of the “Battery 2020 Transfer” announcement.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Calcium as a battery material

Compared to the lithium-ion batteries currently used by industry, the Ca-S battery offers a number of advantages, but also poses challenges for researchers.

Lithium, which has been used in conventional batteries to date, represents the perfect element for an electrochemical cell in many respects: it combines high current storage capacity and cell voltage with fast ion migration.

This enables compact batteries and fast charging and discharging. However, lithium-based systems have an increased fire hazard because dendrites can form during repeated charging, leading to an internal short circuit in the worst case. In addition, lithium deposits on earth are limited and not available on all continents, mining is controversial and it can only be recycled at great expense.

Calcium – a multivalent metal like aluminum, magnesium and zinc – is 400 times more abundant in comparison and therefore inexpensive, as well as being available worldwide and equally distributed. Like lithium, it has a high storage capacity and cell voltage and is also safer in terms of short circuits, since calcium does not form typical dendrites during operation.

The greatest challenge in the use of calcium is its reactivity and the formation of surface layers, whether in contact with air or moisture – or even with the electrolyte used in the battery. The oxidized surfaces block ion diffusion down the road, preventing efficient charging and discharging. The development of a compatible electrolyte thus assumes a key function. In addition, the use of a sulfur cathode generates soluble polysulfides, which can also block the Ca anode – this must also be prevented.

The “CaSino” project has now set itself the goal of achieving significant progress in terms of cycle stability and energy density of calcium-sulfur batteries through innovative material development.

These steps are accompanied by experimental investigations, advanced analytical methods and extensive modeling work. The BMBF-funded joint project will be coordinated by the Institute of Technical Thermodynamics of the German Aerospace Center in Stuttgart during the three-year project period.

From the consortium, the Karlsruhe Institute of Technology (KIT) with its Helmholtz Institute Ulm (HIU) plays a pioneering role in the field of research on calcium batteries. With a non-corrosive boron-based electrolyte, KIT has laid the foundation for further investigation of Ca batteries.

This recent development now enables more stable charging and discharging of Ca batteries over hundreds of cycles. Building on this, KIT together with IoLiTec GmbH, the specialist for ionic liquids, is striving to further improve the already established KIT electrolyte.

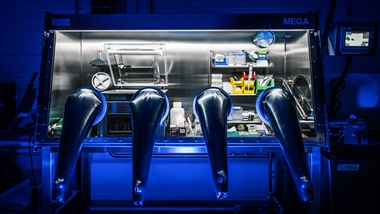

The Research Institute for Precious Metals and Metal Chemistry (fem) is addressing the need for thin and structured Ca anodes, while the DLR Institute for Technical Thermodynamics is developing tailored coatings for this purpose to protect against passivation.

The electrochemical characterization of the new materials will be extended by innovative structural and morphological analysis methods (analytical electron and ion microscopy) at the Natural and Medical Sciences Institute (NMI) at the University of Tübingen.

Furthermore, experimental activities will be supported by atomistic simulations at the University of Ulm and continuum simulations and modeling of the Ca-S cell at the DLR Institute of Technical Thermodynamics.

Finally, a comprehensive consideration of economic and ecological aspects by EurA AG will highlight the potential of the Ca-S system in terms of sustainability, cost and recyclability compared to state-of-the-art battery materials.

The project continues to be supported by an industry advisory board consisting of the companies Alantum, Varta, CustomCells and Accurec. All involved institutions and companies are working together towards the goal of demonstrating the performance of this sustainable energy storage technology based on calcium and sulfur in an industry-compatible battery cell for use as stationary storage.

The consortium

Research Institutions

- DLR: The Institute of Technical Thermodynamics of the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt e.V.; DLR) in Stuttgart has more than 180 employees conducting research in the field of efficient and resource-saving next-generation energy storage and energy conversion technologies. The experimental or model-based development of batteries is located in the departments of Electrochemical Energy Technology and Computational Electrochemistry.

- KIT: As “The Research University in the Helmholtz Association”, the Karlsruhe Institute of Technology (KIT) creates and communicates knowledge for society and the environment. Its goal is to make significant contributions to global challenges in the fields of energy, mobility, and information. To this end, about 9,800 employees work together on a broad disciplinary basis in natural sciences, engineering, economics, and humanities and social sciences. KIT prepares its 22,300 students for responsible tasks in society, industry, and science through research-oriented university studies. KIT’s innovative activities bridge the gap between knowledge and application for the benefit of society, economic prosperity, and the preservation of our natural resources. KIT is one of the German universities of excellence.

- fem: The Research Institute for Precious Metals + Metal Chemistry (fem) in Schwäbisch Gmünd has been conducting research in the fields of materials science, electroplating, and surface technology for 100 years. The fem focuses on the development of innovative and application-oriented materials, coating systems and functionalized surfaces. The development of novel electrode materials is carried out in the Electrochemical Energy Systems (EES) department.

- NMI: The Natural and Medical Sciences Institute (NMI) offers a wide range of analytical systems for nanoanalytics, covering sizes from cm to the atomic scale, and reaching detection limits down to a few ppm. The Nanoanalytics Center of the NMI has successfully applied its scientific and analytical knowledge and methodological expertise in publicly funded research projects, in innovation projects with industry, and in service analytics. As a result, the Nanoanalytics Center is a regional contact point for companies with innovative, materials technology questions and product ideas.

- UUlm: At the Institute of Electrochemistry at the University of Ulm, fundamental processes in energy storage devices and converters are calculated using various theoretical methods and correlated with corresponding experiments. Using a multiscale approach, the focus is on the structure of electrode/electrolyte interfaces and the kinetic processes occurring there.

Industrial partner

- IoLiTec: IoLiTec Ionic Liquid Technologies GmbH, headquartered in Heilbronn, Germany, was founded in May 2003 and is a multi-award winning, innovative, dynamic and goal-oriented company. In addition to a constantly expanding standard product range of currently about 300 ionic liquids as well as about 40 intermediates and 150 nanomaterials, which are sold in gram to ton quantities, IoLiTec offers accompanying R&D services and custom syntheses.

- EurA: As a pan-European technology, innovation and sustainability consultancy, EurA AG has been supporting tomorrow’s market leaders in the innovation process for over 20 years: from research and development of new, sustainable products and processes to market launch and international marketing. EurA AG takes on work of research-accompanying ecological and economic evaluation within the scope of R&D projects in order to support the development of sustainable product and process alternatives in diverse technology fields.

Industry Advisory Board

- Alantum Europe GmbH is a global leader in the research, development and manufacturing of metal foams. Together with our customers – well-known companies from the chemical, automotive and energy sectors – we develop solutions that enable them to master the technical, environmental and legal challenges and thus gain a competitive advantage. Within our partnerships with industry and research, we are continuously working on the development and industrial realization of the next generation of high-performance materials.

Our central hub for materials research and product development of novel catalyst supports for heterogeneous catalysis and electrolysis is located in Munich.

Here, we develop and pilot various manufacturing processes and design, optimize and provide production support for catalysts, catalyst substrates, PTLs, current collectors, electrode materials and MEAs. We operate worldwide and run production lines in Germany, China and South Korea.

- Varta: VARTA AG produces and markets a comprehensive battery portfolio ranging from micro batteries, household batteries, energy storage systems to customized battery solutions for a wide range of applications, and sets the industry standards as a technology leader in key areas. As the parent company of the Group, it operates in the “Lithium-Ion Solutions & Microbatteries” and “Household Batteries” business segments.

The “Lithium-Ion Solutions & Microbatteries” segment focuses on microbatteries, lithium-ion coin power, lithium-ion round cells (lithium-ion large cells) and the lithium-ion battery pack business.

Through intensive research and development, VARTA sets global standards in many areas of lithium-ion technology and in microbatteries, and is thus a recognized innovation leader in the important growth markets of lithium-ion technology and in primary hearing aid batteries.

The “Household Batteries” segment comprises the battery business for end customers, including household batteries, rechargeable batteries, chargers, portable power (power banks) and lights, as well as energy storage devices.

The VARTA AG Group currently employs nearly 4,800 people. With five production and manufacturing facilities in Europe and Asia, as well as distribution centers in Asia, Europe and the United States, VARTA AG’s operating subsidiaries are currently active in over 75 countries worldwide.

- CUSTOMCELLS® is a leading company in the development and series production of state-of-the-art lithium-ion battery cells. Based on flexible manufacturing concepts and state-of-the-art research and production facilities, CUSTOMCELLS® develops and produces high-tech solutions in the field of electrodes, electrolytes, battery cells and battery modules – tailored to the respective requirement profile of its customers. The customer spectrum covers a wide range of industries – with a focus on the automotive, marine and, in the future, aviation sectors. CUSTOMCELLS® operates two production and development sites in Itzehoe and Tübingen: CUSTOMCELLS Tübingen manufactures high-quality lithium-ion batteries in automated series production and is one of the most modern battery cell production facilities in Europe. CUSTOMCELLS Itzehoe is one of the leading producers of customized battery cells and supplies individual solutions for the most demanding applications – from medical technology to autonomous underwater vehicles and electric flying.

- ACCUREC-Recycling GmbH: ACCUREC-Recycling GmbH is a medium-sized company founded in 1995 with the aim of developing and operating innovative recycling technologies for recovering secondary raw materials from batteries. This was initially initiated for environmentally sensitive nickel-cadmium and nickel-metal hydride accumulators, the processing of which in Mülheim/Ruhr is considered to be the most environmentally friendly technology internationally (BAT) thanks to the industrially optimized vacuum distillation technology that has been tried and tested over many years. In the meantime, further recycling processes for alternative battery systems have been developed in cooperation with university research institutes. In line with market developments and increased safety requirements for Li-ion batteries, a new site was established in Krefeld in 2015. The installed technology is based on the BMBF-funded project “EcoBatRec” with the sub-steps of dismantling and mechanical processing. As part of the BMU-funded “MERCATOR” project, the commissioning of a large-scale plant for the thermal processing of used lithium-ion batteries is currently underway. With 80 employees, Accurec generated 18 million euros in sales in 2020 exclusively from the processing of spent batteries. The medium-sized company focuses its personnel expertise on mechanical, pyro- and hydrometallurgical development work through its disproportionately large engineering team. The aim is to expand its technological leadership in the recycling sustainability sector and transfer it as a business model to other growth countries and regions.

READ the latest Batteries News shaping the battery market

Sustainable Batteries Based on Calcium And Sulfur, December 6, 2022