Germany – Development of the battery ecosystem is progressing: almost 17 million euros in funding for a recycling project.

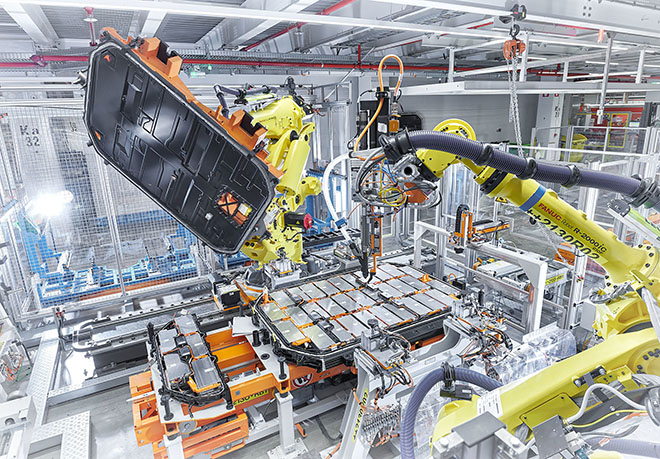

The Federal Ministry of Economics and Climate Protection (BMWK) is funding the development of a holistic recycling approach for lithium-ion batteries with 16.66 million euros. As part of the project, a pilot plant will be built to enable an efficient circular economy of battery materials.

The decision for the “LiBinfinity” project was handed over. The sum goes to a consortium around Licular GmbH.

Project partners are Mercedes-Benz AG, Daimler Truck AG, Primobius GmbH, SMS group GmbH, Clausthal University of Technology, Karlsruhe Institute of Technology (KIT), and Technische Universität Berlin. The funding is part of the funding measure for the “battery ecosystem” of the BMWK.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Michael Kellner, Parliamentary State Secretary at the Federal Ministry for Economic Affairs and Climate Protection, said:

In battery production, closed raw material cycles are our goal: traction batteries should continue to be used in the car after the first use and recycled at the end of the product.

“This increases the ecological benefits of electromobility, reduces Europe’s dependence on raw materials and takes social concerns into account in the value chain.”

“To achieve this, the development of recycling capacities and the development of innovative processes for the recovery of raw materials from lithium-ion batteries are central – and we are promoting both with this project.”

Battery cells “Made in Europe” are to set themselves apart on the world market above all through a high level of sustainability: reuse, disposal and recycling must therefore be taken into account from the outset in development and production.

In the BMWK-funded project “LiBinfinity”, a mechanical-hydrometallurgical process is being developed that completely dispenses with energy-intensive process steps.

A comprehensive approach is being developed – from the development of logistics concepts to the reintegration of recyclate into the life cycle of the battery. With a recycling pilot plant, the approach is brought into a prototypical application. The pilot plant is being built at the Mercedes-Benz site in Kuppenheim and will have an annual capacity of 2,500 tonnes.

The targets proposed by the EU Commission within the framework of the EU battery regulation (which is currently still being agreed in the European trilogue procedure) will lead to significant investments in new recycling capacities and technologies.

From 2031, for example, recyclate quotas are to apply to large traction and industrial batteries. This means that a certain minimum amount of recycled cobalt, lithium and nickel must be used in the new production of lithium-ion batteries.

As part of the measure with the long title “Research in the Priority Funding for Battery Cell Production”, the BMWK is funding a total of almost 40 research associations with around 200 sub-projects. A total of EUR 150 million is available for this purpose.

The funding measure focuses on the topics of battery sustainability and recycling, digitized battery production, testing, certification and quality assurance of batteries as well as the application of new battery cell technologies.

It flanks the two battery IPCEI (Important Projects of Common European Interest), with which the BMWK promotes battery cell production in Germany.

Development of the battery ecosystem is progressing: Almost 17 million euros in funding for recycling project, July 5, 2022