Eurobat – achieving the green deal sustainably – recommendations for the 9 december batteries regulation trilogue.

As the Batteries Regulation proposal negotiations near the end, the European battery manufacturers wish to stress the importance of framing five key issues from the text in the correct way:

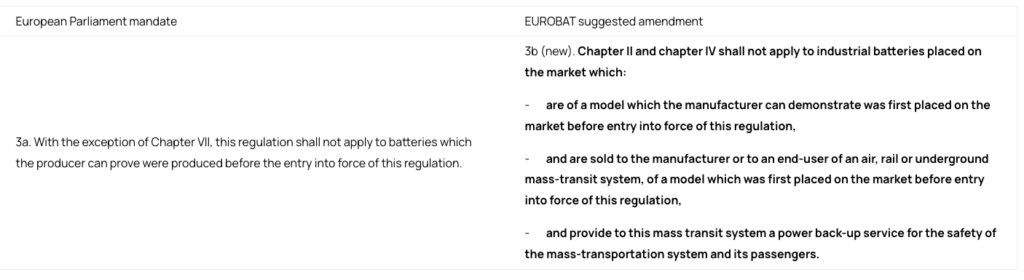

- Grandfather clause, art. 1(3a): a grandfather clause needs to ensure appliances such as trains, aircraft and industrial systems continue operating with batteries designed before the entry into force of the Regulation, and for which a design update is not possible without altering the architecture of the entire application.

- Battery producer definition, art. 2.37: the definition should assign producer status to the appliance or vehicle original equipment manufacturers (OEM) irrespective of the location of the battery manufacturer. OEM should therefore take over end-of-life responsibilities as they are closer to the market where the vehicle or the appliance will be placed and therefore better positioned to efficiently organize the end of life management (2.37).

- Recycled content and information per batch of batteries, art. 8: the original article proposes to gather information per batch of batteries. There is no definition of “batch” in the text, but each battery plant potentially produces several models and batches each day. This requirement would force manufacturers to produce hundreds of certificates every year, with negligible benefit over a single annual carbon content disclosure per battery model.

- Information on dismantling of vehicles, art. 60.3a: if the producer definition is not amended as indicated by EUROBAT (attributing extended producer responsibility to the OEMs), the requirement in art 60.3a should be deleted as batteries manufacturers do not have information on the vehicles and appliances batteries are installed in.

- Carbon footprint calculation, Annex II. Carbon footprint calculation rules should set restrictions to the use of negotiable attribute tracking instruments (Guarantees of Origin or similar instruments) to situations where the laws of physics “demonstrating a temporal and geographical link” are not violated. We therefore support the text of the EP mandate for Annex II point 2a.

We provide in the following a fuller explanation and amendments for each of the points.

Grandfather clause, art. 1.3a

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Once the regulation enters into force, it will rule out the distribution of certain types of batteries, including batteries incorporated in appliances designed before the entry into force of the regulation, for which a redesign is not possible without redesigning a significant part of the electrical system of the application (e.g. in trains, aircrafts, industrial system, etc.).

A grandfather clause needs to be included for (a) spare parts batteries which are incorporated in equipment already in service, and (b) supplies for safety-sensitive applications designed before the entry into force of the regulation and their spare parts.

Battery producer definition, art. 2.37

The definition should assign producer status to the appliance or vehicle original equipment manufacturers (OEM) irrespective of the location of the battery manufacturer.

OEM should therefore assume end-of-life responsibilities, also when the OEM purchases a battery from a manufacturer in the same country, as they are closer to the market where the vehicle or the appliance will be placed, and therefore better positioned to efficiently organize the end of life management.

Recycled content and information per batch of batteries, art. 8

The administrative costs of this measure would put an unjustified strain on battery manufacturers (who would be forced to produce certificates for each batch they produce). A proper level playing field could not be ensured as market surveillance authorities will not have the resources to guarantee the compliance of all products.

Besides, this requirement should not be imposed on every battery model: certain batteries require higher levels of primary materials to deliver better performances. Considering company averages would solve such problems: every company would simply have to provide information on the percentage of cobalt, lead, lithium or nickel recovered from waste present in the batteries placed on the EU market as an aggregated figure.

The overall objective of monitoring (and set up targets, if needed) the use of recycled content would be met in a more efficient and less burdensom way.

End of life information on dismantling of vehicles for producers, art. 60.3

EUROBAT supports the Commission proposal and suggests that should the producer definition not be amended as indicated by EUROBAT (always attributing extended producer responsibility to the OEMs), the requirement in Art 60(3)(a) should be deleted.

In transactions between a battery manufacturer and an OEM in which the manufacturer holds producer status, it cannot be expected that the battery manufacturer supplies information on the dismantling of vehicle and appliances to allow the removal of incorporated batteries.

Only the OEM can do this as it manufactures and owns the vehicle. This is why EUROBAT recommends that in a such supply scenario, the OEM must hold producer status and the battery manufacturer should not.

Limitations to the use of negotiable attribute tracking instruments (Guarantees of Origin or similar instruments) for the carbon footprint calculation, Annex II (art. 7).

We support that a temporal link (hourly) and geographical link (same bidding zone) be required to allow contracts between the energy supply and its use by the economic operator to be used for the carbon footprint calculation. In absence of such links, the country mix shall be used or attribute of the energy delivered via a direct and dedicated link, as the case may be.

About EUROBAT

EUROBAT is the association of the European manufacturers of automotive, industrial and energy storage batteries. EUROBAT represents more than 90% of the automotive and industrial battery industry in Europe though its more than 50 members from across the continent.

EUROBAT members and secretariat work with all stakeholders, such as battery users, governmental organisations and media, to develop new battery solutions in areas of hybrid and electro-mobility as well as grid flexibility and renewable energy storage.

READ the latest Batteries News shaping the battery market

Achieving the Green Deal sustainably, December 7, 2022