Commissioning commences at Vulcan Lithium Extraction Optimisation Plant – Significant step forward for the EU battery critical raw materials supply chain.

Vulcan Energy Resources Limited (Vulcan; ASX: VUL, FSE: VUL, the Company), the renewable energy producer and carbon neutral lithium developer, has commenced commissioning at its Lithium Extraction Optimisation Plant (LEOP).

Cris Moreno, CEO stated:

The commencement of the commissioning of our LEOP facility represents a significant milestone for us, as well as the entire European battery industry.

“By 2030, Europe is likely to face a significant lithium shortage, which could have serious implications for the European battery and automotive industries if domestic supplies are not realised. Vulcan is gearing up to be the first to produce lithium from Europe, for Europe, but also to be the first company worldwide to produce carbon neutral lithium.”

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

“The start of the commissioning of our LEOP facility is a key step toward the implementation of Phase One of our Zero Carbon Lithium™ Project, and in enabling a secure and independent European supply chain for Lithium. This is a great achievement of a determined team.”

“Our pilot plants have already demonstrated the capability of A-DLE, a technology that has been commercially in use globally for decades, on our brines. With this determination, we will continue to advance in the coming months, driving the mobility transition in Europe, and serving as an inspiring example of what is possible, pioneering a carbon free future.“

About LEOP

Vulcan’s LEOP has been built to enable operational readiness when construction of the full commercial plant is completed, to reduce commercial ramp up time. LEOP has the same equipment that Vulcan’s commercial LEP will have, with adsorption columns at a 1:50 scale of the commercial unit, with a greater number of columns in the commercial plant. The LEOP will have the capacity to produce approximately 100 tonnes of lithium chloride solution per annum.

The production volumes at LEOP will signify the firsttonnes of lithium chloride concentrate domestically produced in Europe, and the first tonnes of lithium produced using the commercially proven method of Adsorption – type Direct Lithium Extraction (A-DLE) powered from renewable heat instead of gas.

About Vulcan

Founded in 2018, Vulcan’s unique Zero Carbon Lithium™ Project aims to decarbonise lithium production, through developing the world’s first net carbon neutral lithium business, with the co-production of renewable geothermal energy on a mass scale.

By adapting existing technologies to efficiently extract lithium from geothermal brine, Vulcan aims to deliver a local source of sustainable lithium for Europe, built around a net zero carbon strategy with exclusion of fossil fuels. Already an operational renewable energy producer, Vulcan will also provide renewable electricity and heat to local communities.

Vulcan’s combined geothermal energy and lithium resource is the largest in Europe18F 1

, with license areas focused on the Upper Rhine Valley, Germany. Strategically placed in the heart of the European electric vehicle market to decarbonise the supply chain, Vulcan is rapidly advancing the Zero Carbon Lithium™ Project to targettimely market entry, with the ability to expand to meet the unprecedented demand that is building in the European markets.

Guided by our Values of Integrity, Leadership, Future-focused and Sustainability, and united by a passion for the environment and leveraging scientific solutions, Vulcan has a unique, world-leading scientific and commercial team in the fields of lithium chemicals and geothermal renewable energy.

Vulcan is committed to partnering with organisations that share its decarbonisation ambitions and has binding lithium offtake agreements with some of the largest cathode, battery, and automakers in the world.

As a motivated disruptor, Vulcan aims to leverage its multidisciplinary expert team, leading geothermal technology and position in the European EV supply chain to be a global leader in producing zero fossil fuel, net carbon neutral lithium while being nature positive. Vulcan aims to be the largest, most preferred, strategic supplier of lithium chemicals and renewable power and heating from Europe, for Europe; to empower a net zero carbon future.

Highlights:

- Vulcan has commenced commissioning of its Lithium Extraction Optimisation Plant (LEOP), for the purpose of extraction, purification, and concentration of lithium chloride from brine in the Upper Rhine Valley in Germany. This milestone represents a major step forward by Vulcan and its Zero Carbon Lithium™ Project.

- This also represents significant progress towards enabling domestic European supply chain

independence for lithium as a critical raw material and enabling a more sustainable EV battery production industry in Europe. - The commissioning phase for LEOP is expected to run until October, when first brine will be introduced into the plant for the lithium extraction process to begin.

- Vulcan commenced building its LEOP in 2022, designed as an optimisation, operational training and product qualification facility to enable commercial operationalreadiness for the end of 2025.

- LEOP succeeds Vulcan’s pilot plant, which has successfully operated for 2.5 years, producing lithium chloride from Vulcan’s producing well sites.

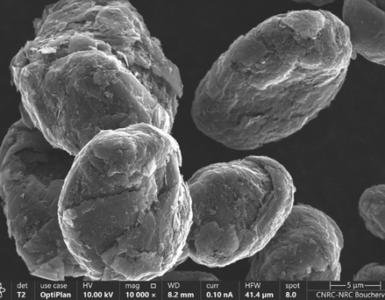

- To extract lithium from brine, Vulcan is using Adsorption-type DLE (“A-DLE”), which has been a commercially proven technology in the lithium industry since the 1990s. A-DLE is also beneficial in terms of low operating costs, greater time efficiency and a lower carbon footprint than legacy industry methods of lithium production.

- Vulcan will use its proprietary sorbent VULSORB® as part of the lithium extraction process.

During the piloting phases, VULSORB® demonstrated higher performance and lower water consumption for lithium extraction compared with commercially available sorbents tested by the Company. - Once the lithium chloride is produced, it will be transported to Vulcan’s downstream Central Lithium Electrolyser Optimisation Plant (CLEOP) in Frankfurt-Höchst where the lithium chloride will be converted into lithium hydroxide, which will be tested by Vulcan’s lithium offtake partners, Stellantis, Volkswagen, Renault, Umicore and LG Energy Solution.

- Vulcan’s Phase One commercial operation is targeting 24,000 tonnes per annum of lithium hydroxide production, to supply its offtakers in Europe with carbon neutral, domestically sourced lithium.

READ the latest Batteries News shaping the battery market

Commissioning commences at Vulcan’s Lithium Extraction Optimisation Plant, August 17, 2023