Ceylon Graphite achieves new outstanding full cell performance of its anode for lithium-ion batteries.

Ceylon Graphite Corp (“Ceylon Graphite”) (TSX-V: CYL) (OTC: CYLYF) (FSE: CCY) announce that it has completed the world’s first full cell testing using spherodized vein graphite materials in commercial size pouch cells following automotive “Original Equipment Manufacturer” (OEM) standards.

Ceylon Graphite’s vein graphite anode material exceeded comparable anodes made with industry standard commercial synthetic graphite and were able to achieve excellent reproducibility in the tests carried out from 2021 through to 2023. This is the first time that spherodized vein graphite materials were tested in a lithium-ion battery full cell.

The tests were conducted at a leading global, independent test facility, Warwick Manufacturing Group (WMG), part of University of Warwick’s Energy Innovation Centre.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

A summary of the test results, completed in February 2023 is highlighted below.

- Repetitive testing of Ceylon Graphite’s unique natural vein graphite material has achieved reproducible outstanding performance results compared to industry standard synthetic graphite:

- Discharge capacity of 161 mAh/g, as compared to the published industry standard of 153 mAh/g

- Small loss in capacity over 120 cycles

- We believe that the impressive performance of our vein graphite material is due to:

- High crystallinity of vein graphite originated highest C% in nature (above 90%)

- In-house purification technology (pending patent) without using any HF (Hydro fluoric) acids

- Ceylon Graphite proprietary spherodizing and formulation technology

- Ceylon Graphite has a mine to battery strategy that will maximize the value of our high-grade Sri Lankan vein graphite by transforming it into anode graphite for the rapidly growing lithium-ion battery market.

- These results provide us the opportunity to:

- Collaborate with potential customers looking for sustainable high-quality anode materials

- Position Ceylon Graphite in the Li-Anode graphite market and achieve potential near term sales

Our latest results for the Full Cells: The cells were tested in a full cell system at a rate of C/5, meaning 5 hours to charge and 5 hours to discharge. Extended cycling exhibited reversible charge/discharge behaviour with less than 15% overall capacity loss over 120 cycles.

The C/5 stable cycling gives an average reversible capacity of 161 mAh/g for the best-performing vein graphite material, compared to 153 mAh/g for standard synthetic graphite measured at the same rate. The cell showed very good stability to cycling at various rates, including at very high current density. The battery could recover the capacity after cycling back at a low rate, indicating high-rate capability.

This graph shows extended cycling results for three materials produced by three different process routes.

Sample 1: HF free purification & standard European spheronisation process

Sample 2: HF free purification & standard Asian spheronisation process

Sample 3: In-house pilot scale HF free electrothermal purification & spheronisation process

It should be noted here that the charge-discharge curve did not show any unusual voltage plateau, further confirming the purity of the materials.

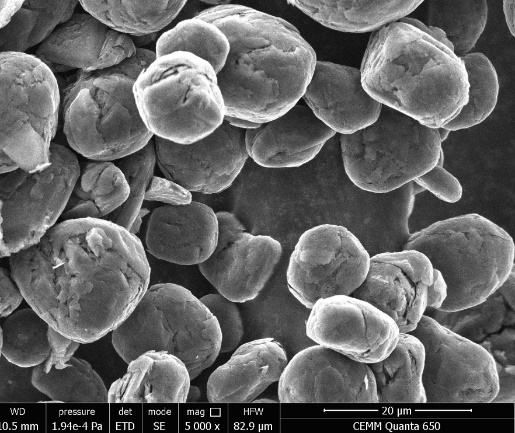

The outstanding performance of Ceylon Graphite’s vein graphite material against current commercially used synthetic graphite is due to the high crystallinity of Sri Lankan vein graphite and the near- perfect morphology of the coated spherodized anode material (shown in the SEM image) produced by proprietary processing and spheroidizing technology of Ceylon Graphite Technologies.

The results prove the suitability of our material for lithium-ion battery anodes for either stand alone or possible blending with synthetic graphite. The HF-free in-house electro thermal purification process is very gentle and did not do any damage to the crystal structure shown in XRD, unlike the HF-based process conventionally used in industry.

SEM Image of Spherodized material

Prof. Mark Copley, Professor at University of Warwick at WMG stated:

These are very promising results and I’m excited at the prospect of Ceylon Graphite using this wonderful natural resource to play a major role in realizing the ‘age of electrochemical power’ and achieving Net Zero.

Dr. Copley is a Professor at WMG, where he is leading the battery manufacturing team and a member of the Faraday Institute.

Prof. Amor Abdelkader from Bournemouth and Cambridge University, who is an expert in carbon materials and energy storage looking deeper into Ceylon Graphite materials, stated that:

Ceylon Graphite Corp’s graphite is one of the best graphite I have tested in Li-ion batteries.

“The stability and purity of the graphite allow us to cycle the battery for a long period with very low capacity loss. I believe it could also go beyond the Li-Ion battery chemistry to other alkali metal battery systems.”

Sasha Jacob, Ceylon Graphite CEO, stated:

Due to the high quality of our material, I expected good results from the initial battery tests, but was excited to see my expectations being far exceeded in terms of the reproducibility as well as performance.

“These results are highly significant for ongoing anode material development at Ceylon Graphite and now can give OEM and Giga factories confidence to carry out Pouch cell testing using our Ceylon vein graphite materials either alone or blended with synthetic materials. “

Conclusion:

The unique characteristics of our Sri Lankan vein graphite combined with our proprietary processing technologies produces a Li-ion battery anode with significantly higher power and energy as shown by the results of tests carried out at WMG.

In addition, we believe that the energy consumption of the end to end process of producing battery grade anode material from vein graphite is the lowest, relative to synthetic and flake graphite because the vein graphite from Sri Lanka does not require extensive primary processing, due to the highest in situ grade in the world with above 90% carbon purity out of the ground.

The test results and Ceylon Graphite’s unique position in the market create optionality for scale-up development, commercial partnerships and sales of advanced materials. Ceylon Graphite’s significant resource positions and our energy products R&D (Ceylon Graphite Technologies (UK)) will allow the company to evolve into a stand-alone battery technology company, with exclusive access to unique and high-performance battery grade graphite at lower cost, sourced from our wholly owned deposits in Sri Lanka.

QUALIFIED PERSON

Dr. Ranjith Premasiri, PhD, MPhil, Bsc, CGeol (UK) FGeol (UK) CGeol (SL), an employee of Sarcon Development (Pvt) Ltd. and not independent to Ceylon Graphite, is a “Qualified Person” as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects and has reviewed and approved the content of this news release.

About Ceylon Graphite Corp.

Ceylon Graphite is a public company listed on the TSX Venture Exchange, that is in the business of mining for graphite, and developing and commercializing innovative graphene and graphite applications and products.

Graphite mined in Sri Lanka is known to be some of the highest grade in the world and has been confirmed to be suitable to be easily upgradable for a range of applications including the high-growth electric vehicle and battery storage markets as well as construction, healthcare and paints and coatings sectors.

The Government of Sri Lanka has granted the Ceylon Graphite’s wholly owned subsidiary Sarcon Development (Pvt) Ltd. an IML Category A license for its K1 mine and exploration rights in a land package of over 120km². These exploration grids (each one square kilometer in area) cover areas of historic graphite production from the early twentieth century and represent a majority of the known graphite occurrences in Sri Lanka.

Further information regarding Ceylon Graphite is available at www.ceylongraphite.com

Sasha Jacob, Chief Executive Officer and Rita Thiel, Chair of the Board of Directors

READ the latest Batteries News shaping the battery market

CEYLON GRAPHITE ACHIEVES NEW OUTSTANDING FULL CELL PERFORMANCE OF ITS ANODE FOR LITHIUM-ION BATTERIES, Vancouver, March 2, 2023