Cabot ENTERATM Aerogel: Mitigating Thermal Runaway Risk in Battery Electric Vehicles,” (Cabot Corporation, Billerica, MA, USA. David Flannery, Xiaofeng Zhang, Peter Pescatore, Sean Sullivan, Jeffrey Gamble, Clare Bannon, Saeed Choudhary; December 2023).

Market Opportunity and Application Overview

The global market for electric vehicles is expanding at an unprecedented rate. Projections indicate substantial growth from 10 million electric vehicles sold annually in 2023 to an estimated 42 million in 2030, a compound annual growth rate of 23%.

By 2030, it is expected that 35% of all new automobiles sold globally will be battery electric vehicles (BEVs). At the same time, stringent global safety regulations are driving the adoption of thermal insulation barriers in lithium-ion batteries used in EVs.

These measures are aimed at mitigating the risk of fires caused by rare, but dangerous, thermal runaway events in EV batteries. Thermal runaway originates in a battery cell and can be triggered by a short circuit, a cell defect, or a mechanical failure caused by an external factor, such as a nail that penetrates the battery pack.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

These thermal events pose dangers to passengers and property and can lead to expensive vehicle recalls by Auto Original Equipment Manufacturers (OEMs). Global safety regulations are mandating that “passengers have at least five minutes to exit the vehicle” (i.e., UN ECE GTR 20 EVS) in the event of a thermal runaway episode.

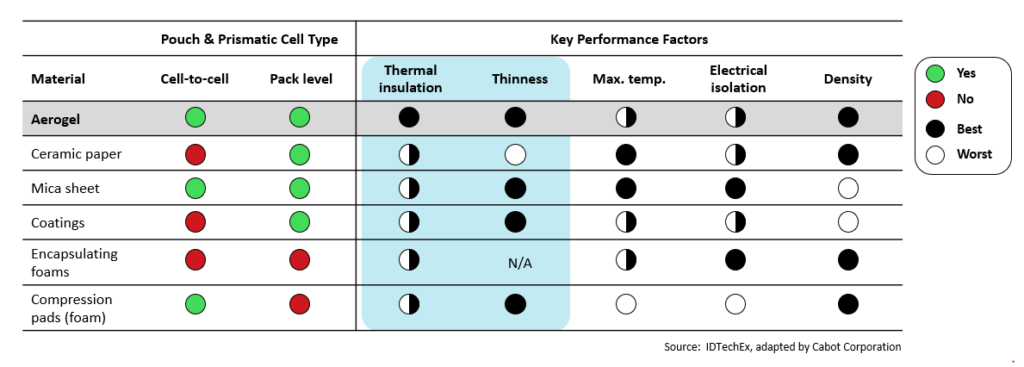

Fire protection materials used within EV battery packs will see increased demand with the growing EV market. Aerogel is expected to be adopted at both the cell and pack level within BEVs due to its superior thermal insulation, compression, and lightweight properties (Figure 1). To date, aerogel has been utilized in pouch and prismatic battery cell types and for both lithium-ion battery cathode chemistries: 1) nickel-cobalt-aluminum/manganese (NCx); and 2) lithium-iron phosphate (LFP). Cylindrical cell types currently use foams and potting agents for thermal management. Thermal barriers for the pouch and prismatic battery applications often build on aerogel’s thermal insulation functionality by combining complementary materials such as foam for compression and mica to prevent electrical arcing.

Figure 1: Fire Protection Materials for Battery Electric Vehicles

Further, the demand for aerogel driven by this battery EV application is expected to grow from approximately $200 million in 2023 to $1.8 billion in 2034. Two-thirds of aerogel demand will be used in thermal barriers placed in between battery cells and one-third will be used at the pack level. Typically, the thinnest thermal barriers (1mm-2mm) are used in between cells, as this is the most space-constrained sub-application, and thicker thermal barriers (3mm-5mm) are used at the pack level, as this is the last line of fire protection between the battery and passenger cabin.

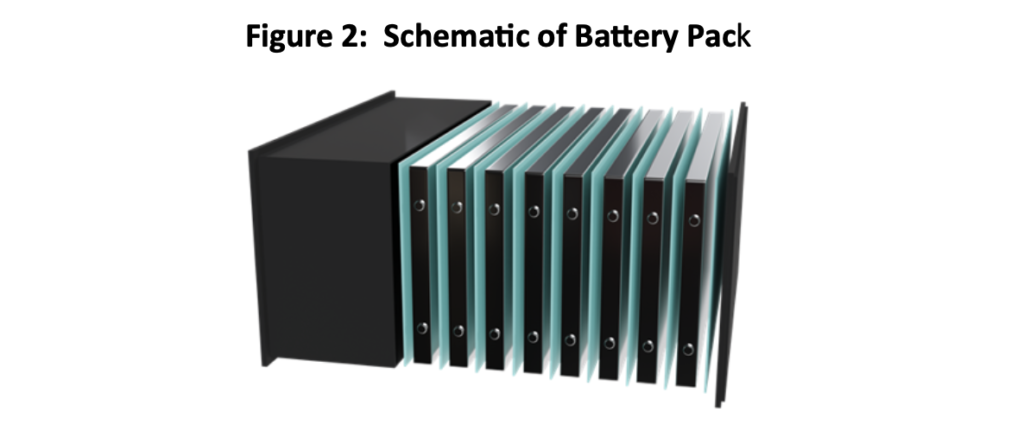

In an EV, many battery cells are stacked closely together, so if one cell goes into thermal runaway, it can cascade to neighboring cells unless adequate thermal insulation is used. Passive thermal barriers shown in green (Figure 2) are placed in between battery cells, in battery modules, and at the battery pack level to contain and slow down thermal propagation.

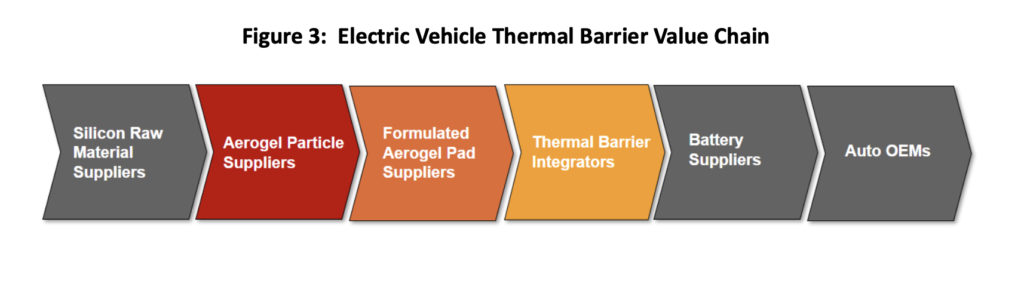

Cabot Corporation participates in the EV thermal management value chain by supplying ENTERATM aerogel particles (Figure 3). Cabot manufactures and markets aerogel particles to downstream formulators that are developing thermal barriers for this application.

ENTERA aerogel delivers enabling insulative performance in the final thermal barriers. Formulators may combine aerogel particles with materials such as glass fibers, ceramic fibers, binders, and other process aids to make aerogel pads and blankets, for example. These pads may then be combined with complementary materials like foam and mica to make the final thermal barriers, which are then sold to auto OEMs and battery suppliers. Thermal barrier buying decisions are made by the entity that designs the battery pack.

Cabot ENTERATM Aerogel Particles – Mitigating Thermal Runaway Risk in Battery Electric Vehicles

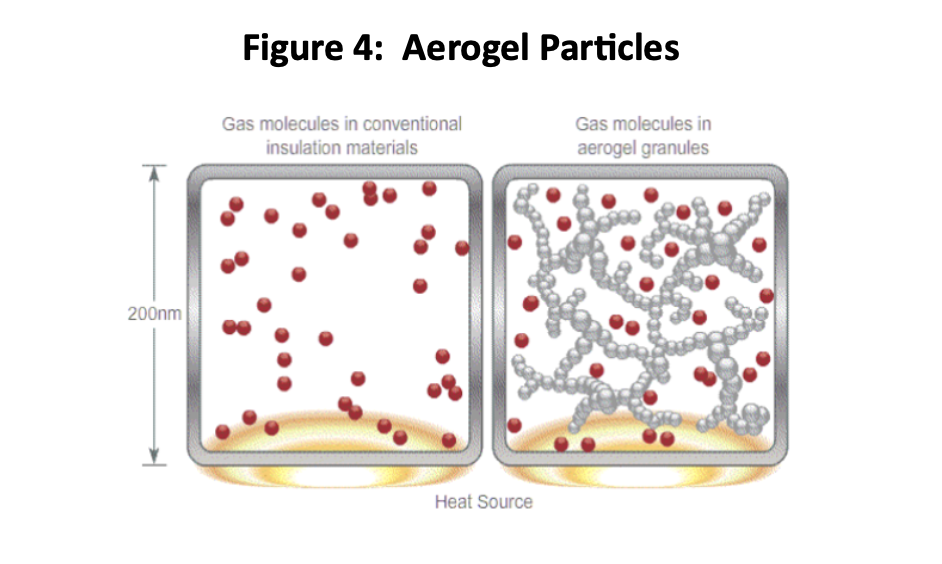

ENTERA aerogel particles enable the manufacture of highly insulative, non-flammable, thin thermal barriers for battery EVs. Comprised of over 90% air, aerogel is one of the best insulators on Earth. Cabot manufactures a unique form of silica aerogel – ENTERA particles in the 0.1mm-1.2mm diameter range with nano-sized pores – which reduces thermal propagation via low thermal conductivity (Figure 4). As a result of aerogel particles’ highly porous morphology, interactions between individual gas molecules containing heat are retarded, dramatically reducing heat transfer through materials that contain them.

ENTERA aerogel particles offer tremendous formulation flexibility and can be incorporated into many types of thermal barriers, including blankets, pads, sheets, films, foams, and coatings. ENTERA aerogel has several attributes that enable break-through performance: 1) exceptionally low thermal conductivity; 2) excellent thermal stability; 3) extremely low density; 4) chemical stability; 5) hydrophobicity; and 6) low dust potential.

ENTERA aerogel offers exceptional insulation in space constrained applications, enabling optimization of battery pack space for additional cells to extend driving range, a key factor for EV buyers. The lower the thermal conductivity, the less heat transfers through a material. Given its extremely low thermal conductivity, ENTERA aerogel enables the thinnest forms possible to do the job required (Figure 5).

The bar chart projects the thicknesses needed for three different materials to deliver the same thermal insulation. Aerogel can reduce the required thermal barrier thickness by a factor of two compared to ceramic paper and by a factor of three compared to silicone foam.

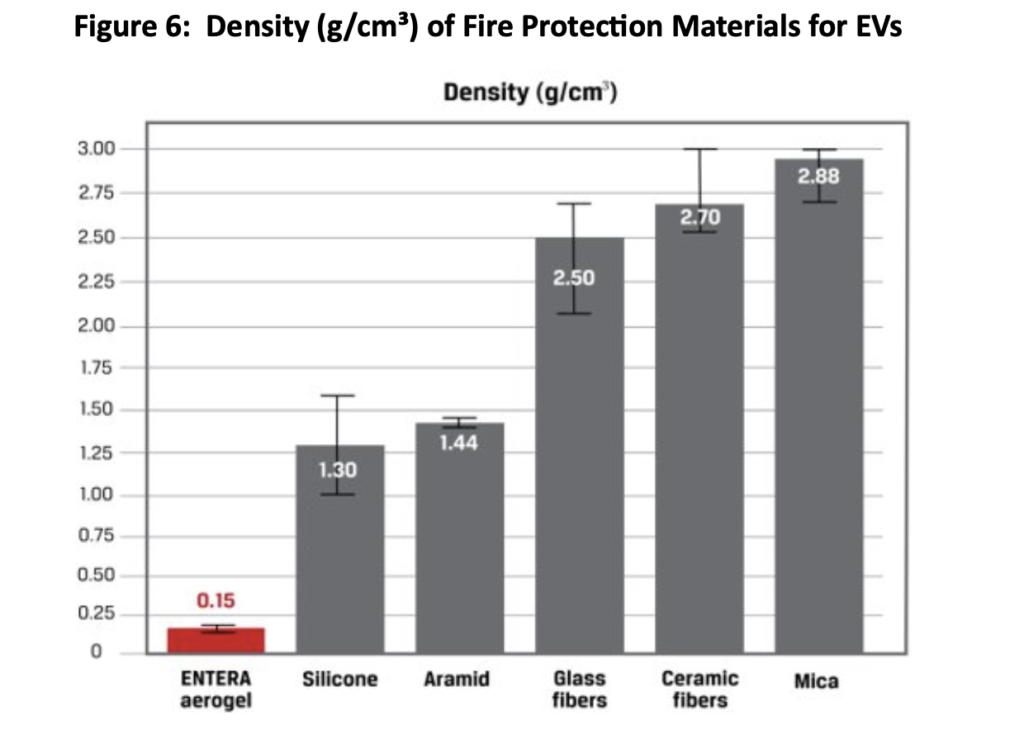

In addition, ENTERA aerogel has excellent thermal stability, even at temperatures reached during thermal runaway. Cabot tests revealed that ENTERA aerogel maintains its very low thermal conductivity (≤ 25 mW/m-K) after being exposed to temperatures as high as 1000 °C for 30 minutes. ENTERA aerogel also has extremely low density relative to other fire protection materials commonly used in electric vehicles (Figure 6). This very low density contributes to vehicle light-weighting, increasing driving range per battery charge, and reducing emissions associated with powering EVs.

ENTERA aerogel particles can also enhance performance in flame retardant coatings that are applied to the inside of battery pack covers. These sprayable aerogel coatings have been shown to be 60%-70% more insulative than ceramic coatings at thicknesses ranging from 2mm to 5mm.

Cabot ENTERATM Aerogel-Enabled Thermal Barriers – Mitigating Thermal Runaway Risk in Battery EVs

ENTERA aerogel is an excellent insulation additive in thermal barriers for battery EVs to minimize thermal runaway risks. Cabot has developed aerogel pad prototypes with ENTERA aerogel to demonstrate the performance level that can be achieved with our particles. ENTERA aerogel can be formulated with glass fibers, ceramic fibers, and other materials. The prototype pads are not being offered for sale by Cabot. The particles enabled the production of thin pads (1mm-2mm, or greater) with good thickness uniformity. The pads also delivered excellent thermal insulation as indicated by thermal conductivity of less than 25 mW/m-K at room temperature, were non-flammable, and passed the UL94 V0 Test.

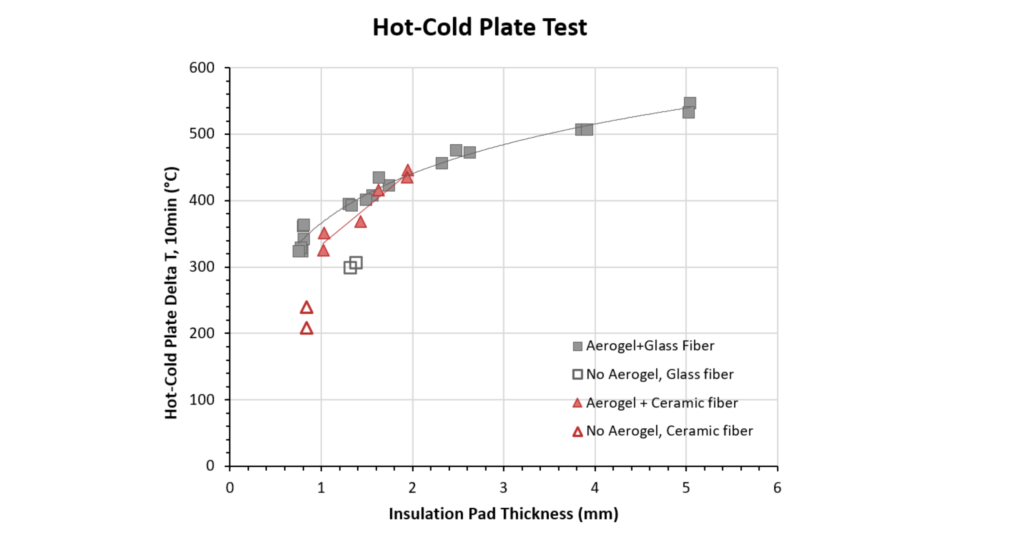

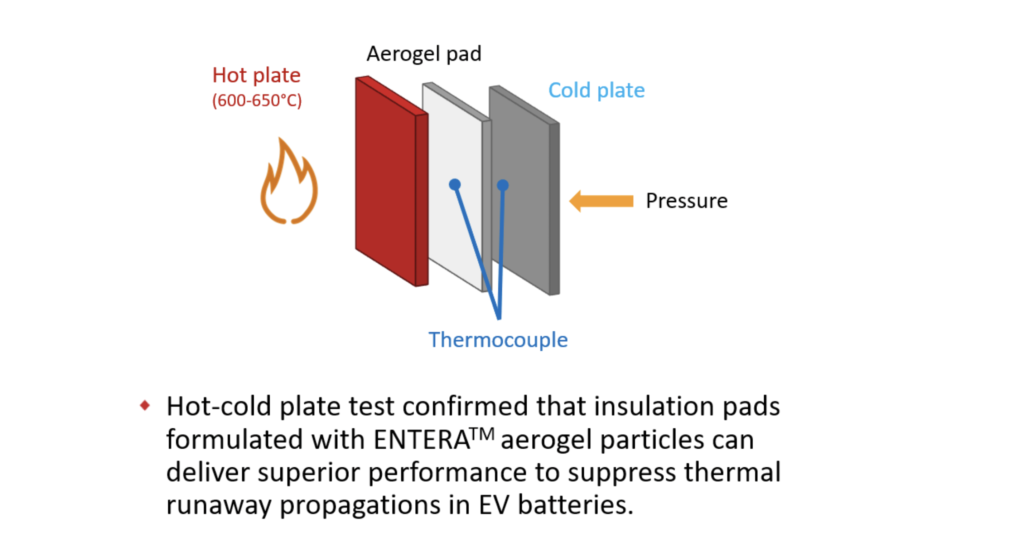

More importantly, Cabot conducted “hot-cold plate” tests, commonly used by battery suppliers and OEMs, which confirm the level to which insulation pads formulated with ENTERAaerogel particles can suppress thermal propagation in EV batteries. A hot-cold plate test system is used to simulate thermal runaway conditions, where the hot plate simulates a thermal runaway trigger cell, and the cold plate serves as a normal cell. An aerogel pad is inserted between the hot and cold plates to reduce thermal propagation (Figure 7). Thermocouples are attached to both the hot side and cold side of the plates in contact with the aerogel pads and a pressure of 50 psi is applied to the pad between the hot and cold plates. The hot plate is heated from room temperature to 650°C and the temperature is recorded for 10 minutes.

Figure 7: Performance Validation of ENTERA Aerogel Pads

This performance testing revealed that pads containing ENTERA aerogel can improve insulation performance by 100°C versus either glass or ceramic fiber pads of the same thickness that do not contain aerogel. The temperature difference (Delta-T) between hot and cold sides is critical as it is a measure of the level of resistance to thermal propagation (heat transfer) from the thermal runaway trigger cell to adjacent cells.

A high Delta-T can potentially signify that the thermal runaway event can be contained to one cell and thus minimize the potential that it spreads throughout the battery pack, which ultimately can offer sufficient time for passengers to exit the vehicle. Lithium-ion battery thermal runaway onset and peak temperatures differ among cathode chemistries (e.g., NCx, LFP) and ENTERATM aerogel-enabled pads can be made in a range of thicknesses to provide the requisite insulation to meet the various requirements of EV batteries.

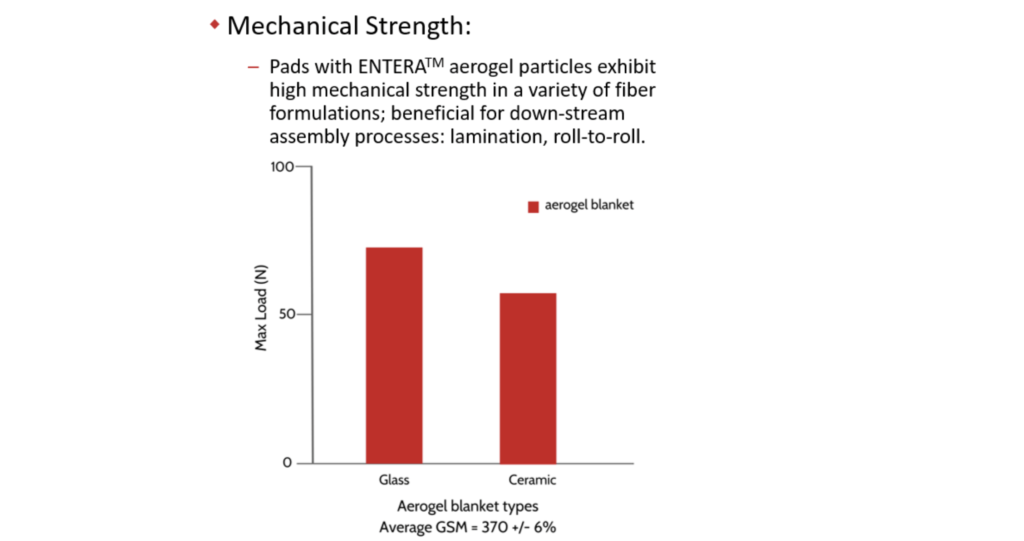

Further, Cabot’s prototype thermal barrier pads made with ENTERA aerogel exhibit strong mechanical properties that enable them to be used in common downstream processes like lamination, adhesion, and roll-to-roll manufacturing without breaking (Figure 8).

Figure 8: Mechanical Properties of ENTERA-Enabled Aerogel Pads

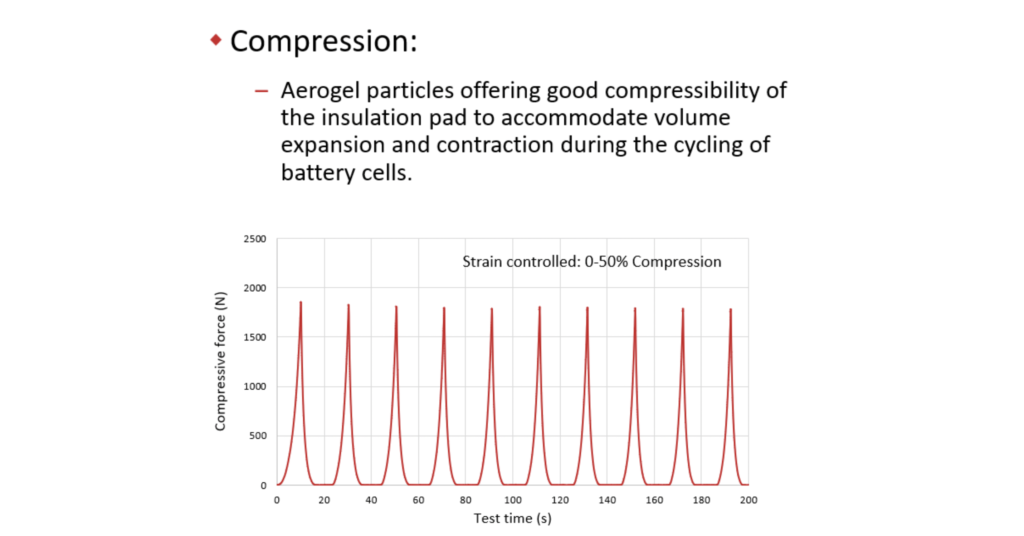

The prototype pads retained very high tensile strength even with a 40% mass of aerogel particles. In addition to the high strength requirement during the assembly process, aerogel pads inserted between cells must have good elasticity as the cell will expand and contract during charging/discharging cycles. In a cyclic compression test (0-50% compression), pads containing ENTERA aerogel particles demonstrated excellent elasticity during cycling.

Finally, Cabot demonstrated that ENTERA aerogel-enabled insulation pads are compatible with adhesives and complementary materials often incorporated into final thermal barriers. This can include foam compression pads as well as mica sheets to prevent electrical arcing, thereby enabling the manufacture of multilayer thermal barrier structures with additional functionality.

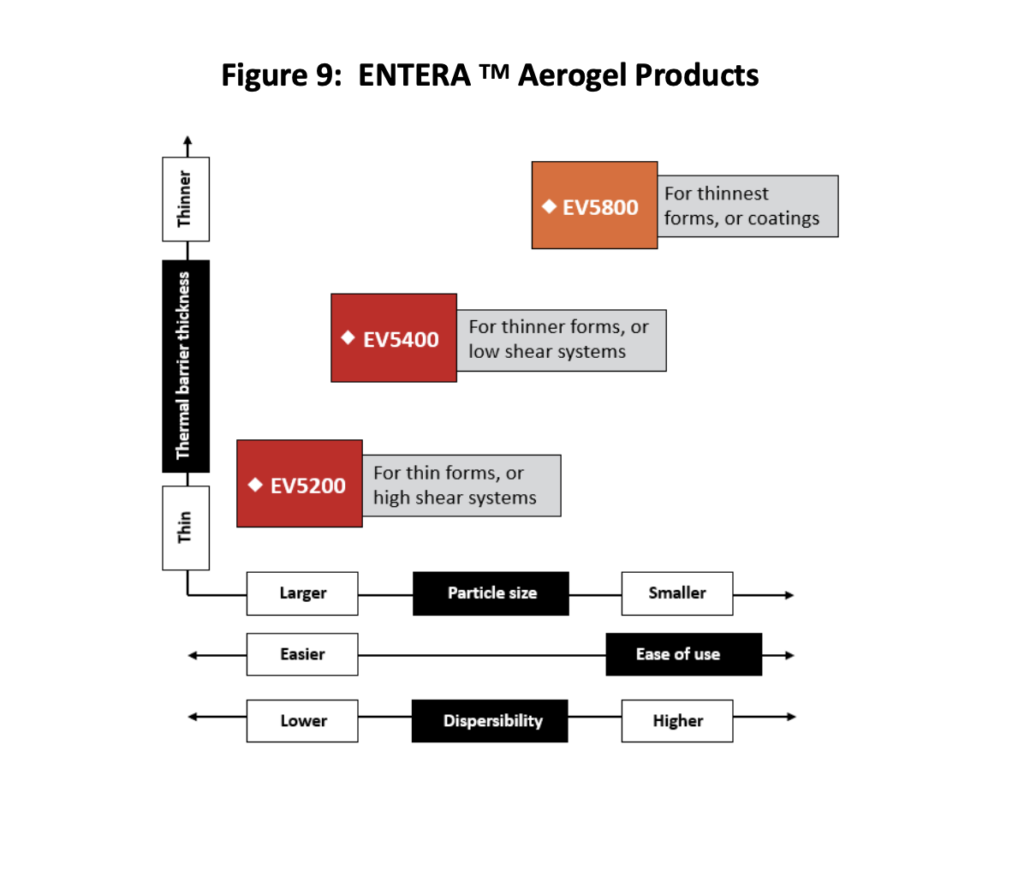

ENTERATM Aerogel Product Offering

Cabot launched ENTERA aerogel for electric vehicles in 2023 with an emphasis on offering formulation flexibility and enabling insulative performance for battery EVs. The ENTERA aerogel product portfolio consists of three products: EV5200, EV5400 and EV5800 (Figure 9). For formulators developing blankets, pads, sheets, films and foams, ENTERA EV5200 aerogel is suitable. If challenges are encountered dispersing EV5200, ENTERA EV5400 aerogel is an alternative. For customers developing sprayable flame-retardant coatings or very thin insulation layers, ENTERA EV5800 is suitable due to its small particle size and narrow particle size distribution.

Conclusion

Stringent global safety regulations are driving the adoption of thermal barriers in EV battery packs, ensuring passengers can safely exit the vehicle in case of thermal runaway, which can lead to fires. Aerogel is one of the best insulation materials on Earth, making it the ideal solution for space-constrained applications like those in EV battery packs.

Cabot’s ENTERA aerogel particles offer excellent formulation flexibility and can be incorporated into various product forms using different manufacturing methods. Moreover, ENTERA particle-enabled aerogel pads have been shown to meet stringent EV battery requirements to mitigate the risk of thermal runaway. Cabot offers three ENTERA aerogel particle products to meet the needs of formulators developing thermal barriers for battery EVs.

1 – Rho Motion: EV & Battery Market Analysis (2023)

2 – EV sales from Bloomberg NEF Updated Vehicle Outlook (2022)

3 – “Aerogels 2024-2034: Technologies, Markets and Players,” Dr. James Edmondson and Dr. Richard Collins, IDTechEx, 2023

READ the latest Batteries News shaping the battery market