BOLD Valuable Technology is pleased to unveil BOLDair, a superior aviation battery system to power electric or hybrid flight. The latest high-performance product launch closely follows a variety of projects, key in the development of applications in the fields of motorsport, marine and aviation, since the company’s inception in 2019.

Alongside this important launch, the first high volume battery project saw production start at BOLD HQ in Barcelona in the beginning of April, the largest volume project for BOLD to date, with a 60 MWh production run of 1500 batteries.

BOLD’s expertise in developing and manufacturing high performance battery systems is suited to the needs of electric aviation. With safety front of mind, BOLD is dedicated to bringing this technology into play, enabling commercially viable aviation applications. BOLD Air’s design focusses strongly on safety aspects and a realistic certification path, without compromising performance.

This development is a standard platform, designed to be integrated into partners unique systems. Already in talks with several key industry players, BOLD is gaining global interest in the aviation sector.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

BOLD has been gearing up with AS9100 (a quality management system for the aerospace industry), a new chief of Airworthiness and a functional safety team to further prove the organisation’s commitment to obtaining the aviation regulators certification. As the process will take several years, BOLD is willing and ready to join forces with partners to reach this critical goal of achieving suitability for safe flight.

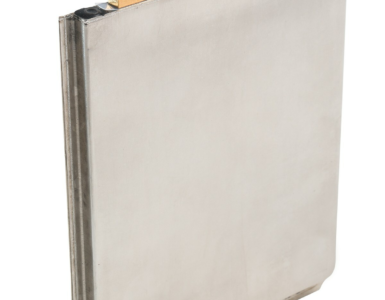

The latest high voltage battery system’s performance is a differentiating factor. Unlike existing batteries, it features a gravimetric efficiency of 285 Wh/kg making BOLD front runner in the race to electric aviation viability. This includes a full PDU, with contactors, connectors, BMS and a conditioning interface capable of providing passive and active liquid or air thermal management.

BOLD has been diligent in performing approximately 100 thermal runaway tests onsite over the past year, to fine tune this design. A deep understanding has been developed of the cell chemistry; interaction with the mechanical integration; fluid dynamics; test techniques and how these effect the mechanical integration, venting strategy, and safety diagnostics.

The organisation moved away from lithium metal cells at the end of last year due to the complexity and risk of the chemistry. Focusing on silicone anode chemistries that are more mature has allowed BOLD to create a certifiable and commercially viable solution.

The BOLDair prototype will be exhibited at the Vertical Flight Society’s 79th Annual Forum & Technology Display in West Palm Beach, Florida from the 16th to 18th of May. The mockup will feature the modules vast capabilities and safety features. BOLD’s specialists will be manning an exhibition stand at the three-day event, eager to answer any questions on the module.

Production will continue in May and throughout the rest of 2023. The Development Validation Plan (DVP) begins in June. This includes thermal runaway testing, electro-thermal endurance testing and DO160G testing which will further prove the battery system’s safety characteristics and capabilities.

BOLD Valuable Technology is pleased to unveil BOLDair, a superior aviation battery system to power electric or hybrid flight. The latest high-performance product launch closely follows a variety of projects, key in the development of applications in the fields of motorsport, marine and aviation, since the company’s inception in 2019.

Alongside this important launch, the first high volume battery project saw production start at BOLD HQ in Barcelona in the beginning of April, the largest volume project for BOLD to date, with a 60 MWh production run of 1500 batteries.

BOLD’s expertise in developing and manufacturing high performance battery systems is suited to the needs of electric aviation. With safety front of mind, BOLD is dedicated to bringing this technology into play, enabling commercially viable aviation applications. BOLD Air’s design focusses strongly on safety aspects and a realistic certification path, without compromising performance.

This development is a standard platform, designed to be integrated into partners unique systems. Already in talks with several key industry players, BOLD is gaining global interest in the aviation sector.

BOLD has been gearing up with AS9100 (a quality management system for the aerospace industry), a new chief of Airworthiness and a functional safety team to further prove the organisation’s commitment to obtaining the aviation regulators certification. As the process will take several years, BOLD is willing and ready to join forces with partners to reach this critical goal of achieving suitability for safe flight.

The latest high voltage battery system’s performance is a differentiating factor. Unlike existing batteries, it features a gravimetric efficiency of 285 Wh/kg making BOLD front runner in the race to electric aviation viability. This includes a full PDU, with contactors, connectors, BMS and a conditioning interface capable of providing passive and active liquid or air thermal management.

BOLD has been diligent in performing approximately 100 thermal runaway tests onsite over the past year, to fine tune this design. A deep understanding has been developed of the cell chemistry; interaction with the mechanical integration; fluid dynamics; test techniques and how these effect the mechanical integration, venting strategy, and safety diagnostics.

The organisation moved away from lithium metal cells at the end of last year due to the complexity and risk of the chemistry. Focusing on silicone anode chemistries that are more mature has allowed BOLD to create a certifiable and commercially viable solution.

The BOLDair prototype will be exhibited at the Vertical Flight Society’s 79th Annual Forum & Technology Display in West Palm Beach, Florida from the 16th to 18th of May. The mockup will feature the modules vast capabilities and safety features. BOLD’s specialists will be manning an exhibition stand at the three-day event, eager to answer any questions on the module

Production will continue in May and throughout the rest of 2023. The Development Validation Plan (DVP) begins in June. This includes thermal runaway testing, electro-thermal endurance testing and DO160G testing which will further prove the battery system’s safety characteristics and capabilities.

Early Thermal Runaway Test on a Single Cell Test Rig

Both hardware and software teams at BOLD continue to strive to advance the technology and organisation required for the control system of an aviation battery system. By implementing the required functional safety and aviation processes for software and hardware development, BOLD´s goal is to ensure this is a sellable product. BOLD is taking ownership of all hardware and software development activities required to meet industry standards.

Besides safety, BOLD´s further objectives for this development included:

- Versatility to fit eVTOL and eCTOL applications.

- Create a robust design for harsh environmental and mechanical conditions.

- Push to be in market faster than typical aviation products.

- Build dedicated teams adapted to collaborate with established aviation partners for fast integration.

Bernat Carreras, BOLD CEO and Founder, said:

BOLDAir is undoubtedly some of our finest work. Combining our knowledge of composite materials and control systems developments with thousands of testing hours has allowed us to create a battery system that not only performs but is a safe and viable solution close to 300 Wh/kg for battery powered aircrafts.

“Safety is the number one priority in aviation and front of mind when designing and manufacturing our battery systems. This module marks a significant step closer to superior energy density and safety in electric aviation, and we couldn’t be more thrilled to be working with our partners on vehicle integration.”

Chris Rini, Principal Engineer of Electrification at BOLD, added:

Pushing the limits of performance, safety and functionality has given the BOLD team the challenge of a lifetime.

“I could not be prouder of how far the team has come and look forward to seeing our efforts put into practice soon.”

The company is targeting the first certifiable product by 2025 and is aware of the complexity and effort this will take. BOLD will continue the development of high voltage battery systems for the aviation industry after this initial version. Integrating the best cells the industry can offer, and having the flexibility to adapt as lithium-ion chemistries continue to evolve, will ensure that BOLD can continue to produce battery systems with the highest levels of performance.

READ the latest Batteries News shaping the battery market

One Step Closer to Take-Off for Electric Aviation with BOLDair, May 17, 2023