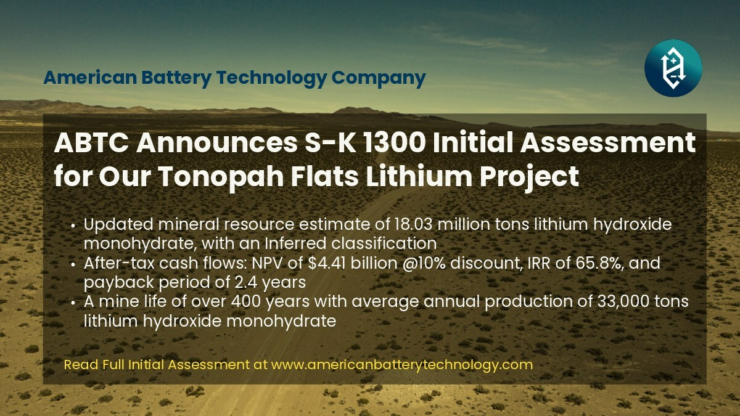

American Battery Technology Company Announces S-K 1300 Initial Assessment for its Tonopah Flats Lithium Project.

American Battery Technology Company (ABTC) (NASDAQ: ABAT), an integrated critical battery materials company that is commercializing its technologies for both primary battery minerals manufacturing and secondary minerals lithium-ion battery recycling, is pleased to announce a positive Initial Assessment for its Tonopah Flats Lithium Project (TFLP) located in Big Smoky Valley, near Tonopah, Nevada.

In February 2023, ABTC published its Maiden Resource Report for the TFLP which identified it as one of the largest known lithium resources in the U.S., and now this U.S. SEC S-K 1300 Initial Assessment (similar to a Preliminary Economic Assessment under Canadian NI 43-101 standards) updates this resource report by also including:

- Additional data from the company’s Drill Program II

- Mineral processing and metallurgical testing specifically with ABTC claystone material

- Capital and operating costs of a commercial-scale 33,000-ton/year lithium hydroxide monohydrate (LHM) facility

- Economic analysis for the lifetime of the project

- Recommended next steps for the TFLP project

Ryan Melsert, ABTC CEO, said:

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

We are excited to have expanded upon our Maiden Resource Report from this past Spring with this Initial Assessment to further refine the analysis of the magnitude and quality of this unconventional, domestic lithium resource.

“And also to detail the financial competitiveness of bringing this resource and commercial-scale lithium hydroxide refinery to market. There is extremely large demand for U.S.-based battery grade lithium products, especially in the hydroxide form that can enable the manufacturing of high energy density cathode materials. Enhanced by the support of our U.S. Department of Energy grants, the economics of this project are very compelling and result in a full project payback period of only 2.4 years.”

In order to evaluate and standardize the performance of ABTC’s claystone material, initially two conventional processing routes were employed in empirical trials to manufacture battery grade LHM from bulk samples collected from the ABTC TFLP resource.

- Low-Temperature, Mineral Acid Process: The Initial Assessment concluded that with ABTC’s claystone material utilizing a conventional low-temperature mineral acid processing route, very high lithium recovery efficiencies can be achieved (>90%), however, as is emblematic of this approach the selectivity of lithium to other elements was low. This resulted in the need for complex and chemical reagent intensive purification and conversion processes to produce battery grade LHM.

- Salt Roasting Thermal Treatment: The Initial Assessment concluded that with ABTC’s claystone material utilizing a salt roasting thermal treatment route, moderate lithium recovery efficiencies can be achieved (>65%), however, the lithium selectivity was very high and battery grade LHM can be manufactured with simple and low-cost purification and conversion processes.

For the purposes of this Initial Assessment, the economic analysis was performed utilizing the conventional salt roasting thermal treatment route, as the combination of moderate lithium recovery, very high lithium selectivity, and simplified purification and conversion processes resulted in the most attractive overall production costs.

Independent from these commercially available conventional processes, ABTC has also developed its own processes for the extraction of lithium from its claystone materials, the purification of these lithium intermediates, and their conversion to battery grade lithium hydroxide crystals. While this Initial Assessment includes economics from commercially available processes applied to TFLP claystone material, ABTC intends to utilize the data from its internally-developed processes in future reports.

ABTC has recently completed a Drill Program III at TFLP consisting of 8 core drill holes with approximately 6,700 feet of drilling, and the data from this drill program is not included in this Initial Assessment. This data will be integrated with data from earlier drill phases and will be included in a future updated mineral resource estimate and economic analysis.

TFLP Initial Assessment Highlights

Financial Highlights:

- LHM production cost: $4,636/ton

- Lithium refinery capital costs: $455 million

- Total mine and refinery project capital costs: $1.06 billion

- After-tax NPV, @10%: $4.41 billion

- After-tax Initial Rate of Return: 65.8%

- Project payback period: 2.4 years

- Total 50-year project revenue: $50.0 billion

- Total 50-year operating costs: $9.80 billion

Project and Resource Highlights:

- Lithium resource size, Inferred classification: 18.03 million tons LHM

- Average lithium hydroxide monohydrate grade: 3,815 ppm

- Total resource size: 5.4 billion tons of claystone

- Average annual production: 33,000 tons LHM

- Project lifetime: 50 years

- Life of Mine: The economic analysis presented in this report details a project with a life of approximately 50 years, however, the estimated lithium resources could support a mine life in excess of 400 years at the mining and processing rates of this Initial Assessment

- Mining Method: Simple, near-surface open pit mining method with concurrent reclamation planned to restore land in stages soon after an area is mined rather than waiting for all mining to be completed

- Royalties: ABTC owns 100% of the unpatented lode mining claims comprising the TFLP property with no royalties

Next Steps for Project Commercialization:

- Publication of updated Initial Assessment, including data from Drill Program III, updated mineral resource assessment, and updated economic analysis

- Completion of Drill Program IV and publication of Pre-Feasibility Study (PFS)

- Hydrological and Geotechnical Drill Programs of TFLP property

- Complete Baseline Environmental Studies and National Environmental Protection Act (NEPA) review process

- Complete commissioning and begin operations of pilot refinery system that will process TFLP claystone materials, and utilize this data from a continuously operating integrated refinery to further optimize the design of the commercial scale refinery

- Complete engineering design for ABTC’s commercial refinery with Black & Veatch

The information contained in this press release is qualified in its entirety by reference to the complete text of the Initial Assessment, including but not limited to the mineral resource estimates and economic analysis. To read the full ABTC Tonopah Flats Lithium Project Initial Assessment, visit: www.americanbatterytechnology.com/projects/tonopah-flats/

Qualified Person

The mineral resource estimates presented in the ABTC Tonopah Flats Initial Assessment were performed by third-party, qualified person RESPEC, LLC and were classified by geological and quantitative confidence in accordance with the Securities and Exchange Commission (SEC) Regulation S-K 1300.

Initial Assessment

An Initial Assessment is a preliminary technical and economic study of the economic potential of all or parts of mineralization to support the disclosure of mineral resources. The Initial Assessment must be prepared by a qualified person and must include appropriate assessments of reasonably assumed technical and economic factors, together with any other relevant operational factors, that are necessary to demonstrate at the time of reporting that there are reasonable prospects for economic extraction. An Initial Assessment is required for disclosure of mineral resources but cannot be used as the basis for disclosure of mineral reserves.

Inferred Resource

An Inferred Resource is that part of a mineral resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. The level of geological uncertainty associated with an Inferred Resource is too high to apply relevant technical and economic factors likely to influence the prospects of economic extraction in a manner useful for evaluation of economic viability. Because an Inferred Resource has the lowest level of geological confidence of all mineral resources, which prevents the application of the modifying factors in a manner useful for evaluation of economic viability, an Inferred Resource may not be considered when assessing the economic viability of a mining project and may not be converted to a mineral reserve.

READ the latest Batteries News shaping the battery market

American Battery Technology Company Announces S-K 1300 Initial Assessment for its Tonopah Flats Lithium Project. source