Altech Chemicals achieves lithium-ion battery breakthrough for graphite-silicon anode, and it advances plans to produce high purity alumina.

[Proactive Investors] Altech Chemicals Ltd (ASX:ATC) is aiming to become one of the world’s leading suppliers of 99.99% (4N) high purity alumina (HPA) through the construction and operation of a 4,500 tonnes per annum (tpa) HPA processing plant at Johor, Malaysia.Feedstock for the plant will be sourced from the company’s 100% owned kaolin deposit at Meckering, Western Australia and shipped to Malaysia.

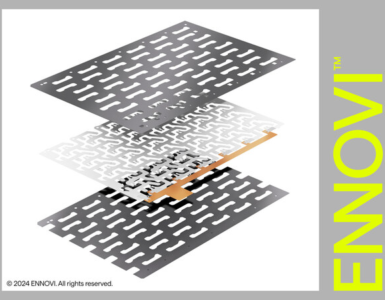

HPA is a high-value, high margin product forecast to be increasingly used by lithium-ion battery manufacturers, both as a coating on the battery’s separator sheets and also as a possible nano-coating for application to battery anode materials such as graphite and silicon to improve battery performance, safety, chargeability and life.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Coating graphite with alumina

2021 has been a busy year for Altech with managing director Iggy Tan and his team focussed on progressing funding options for the company’s proposed Malaysian HPA plant, which has included advancing a Green Bonds offering, a direct project level equity investment for up to 49% of the project, and additional equity investment in Altech.

In September 2020, Altech announced that it had developed an innovative method for the coating of graphite particles, typical of those used in lithium-ion batteries, with a nano layer of alumina.

The development, testing and expansion of this technology to include the coating of silicon particles with alumina is ongoing at the company’s dedicated research and development facility in Perth.

The facility was officially opened in July 2021 and has allowed Altech to conduct a range of research, development and test work (including battery tests) to refine its coating methods and technology.

“Cracked the silicon barrier”

In late November 2021, Altech achieved a breakthrough in lithium-ion technology with its research and development lab in Perth creating a workable graphite-silicon anode.

After almost 12 months of challenging work, Altech says it has finally “cracked the silicon barrier” and successfully produced and tested a series of lithium-ion battery anode materials that have about 30% higher retention capacity compared to conventional anode materials.

Altech successfully combined silicon particles – that had been treated with its innovative proprietary technology – with regular battery-grade graphite to produce a lithium-ion battery electrode containing a composite graphite-silicon anode.

Investors have responded strongly, with shares trading at A$0.14 by the end of November, an increase of 40% compared to the beginning of the month.

Breakthrough for lithium-ion industry

Iggy Tan, Altech managing director said following the successful production:

This major achievement is not just a significant breakthrough for Altech, but also for the lithium-ion battery industry generally.

“Especially so, given the 2020 public statement by US electric vehicle manufacturer Tesla, which said that its aim is to increase the amount of silicon in its batteries to achieve step-change improvements in energy density and battery life.”

“A 30% higher energy capacity lithium-ion battery would translate not just to significant cost benefits, but also to potentially increased range for electric vehicles.”

“Phase 2 of Altech’s planned research and development program will see the company strive to improve on the 30% energy increase and could include the assembly of a pilot plant.”

“In terms of potential commercialisation of its technology, the company’s 75%-owned subsidiary Altech Industries Germany GmbH has already commenced a pre-feasibility study for the construction of a 10,000 tonnes per annum battery materials plant in Saxony, Germany, to service the burgeoning European lithium-ion battery market.”

Altech’s managing director Iggy Tan spoke to Proactive about the breakthrough:

Conservative (bank case) cash flow modelling of Altech’s HPA project shows a pre-tax net present value (NPV) of US$505.6 million at a discount rate of 7.5%.

The project is forecast to generate annual average net free cash of ~US$76 million at full production, with an attractive margin on HPA sales of ~63%.

German engineering firm SMS group GmbH (SMS) is the appointed EPC contractor for the construction of Altech’s Malaysian HPA plant.

SMS has provided a US$280 million fixed-price turnkey contract and has proposed clear and concise guarantees to Altech for plant throughput and completion.

Altech has been successful in securing senior project debt finance of US$190 million from German government-owned KfW IPEX-Bank as senior lender.

In addition to the senior debt, Altech is pursuing various additional funding options including a listed Green Bond and selling a direct project interest of up to 49% in its HPA project.

HPA plant in Saxony, Germany

During the first quarter of 2021, Altech’s 75% owned German subsidiary Altech Industries Germany

GmbH (AIG) commenced a preliminary feasibility study (PFS) for the construction of a high purity alumina (HPA) battery materials coating plant in Saxony, Germany.

The PFS has assumed a plant coating capacity of 10,000tpa (35 tonnes per day) and the location would be at the Schwarze Pumpe Industrial Park in Saxony, Germany – where AIG has an option to acquire a ~14 hectares site.

The results of the PFS are expected within the coming months.

$14.5 million rights issue

Altech continued to receive strong support from its shareholders during 2021, as demonstrated by the fully subscribed rights issue that was completed in January 2021.

The company raised $14.5 million from the offer which was underwritten by Altech’s major shareholders Deutsche Balaton/Delphi and the Melewar group.

HPA usage

The use of HPA in the manufacture of lithium-ion batteries is forecast to rapidly increase, in line with battery use in in electric vehicles, and an ever-increasing number of consumer goods applications.

Lithium-ion battery manufacturers are already using HPA as a coating for the polymer anode/cathode separator sheets within the battery in order to reduce separator shrinkage and the likelihood of resultant battery combustion.

HPA is also a critical ingredient required for the production of synthetic sapphire.

Synthetic sapphire is used in the manufacture of substrates for LED lights, semiconductor wafers used in the electronics industry, and scratch-resistant sapphire glass used for wristwatch faces, optical windows and smartphone components.

It is worth noting that there is no substitute for HPA in the manufacture of synthetic sapphire.

HPA demand

HPA is a premium-priced material (selling in the range of US$15 to US$50 per kg) with forecast significant annual demand growth driven primarily by two fast-growing industries: the rapidly expanding lithium-ion battery industry; and the sapphire/LED industry.

The use of 4N HPA in the production of lithium-ion batteries continues to evolve, driven by the development of more energy-dense batteries to serve the surging electric vehicle (EV) and renewable energy storage markets.

Altech has established its own dedicated research and development laboratory, which is enabling the company to refine its materials coating technology and conduct a range of lithium-ion battery test work.

Highlights:

- Altech aims to construct a 4,500 tonnes per annum high purity alumina (HPA) processing plant at Johor, Malaysia

- Feedstock for the plant will be sourced from the company’s kaolin deposit at Meckering in WA

- HPA is forecast to be increasingly used by lithium-ion battery manufacturers, both as a coating on the battery’s separator sheets and as a possible nano-coating for application to battery anode materials

- Altech has developed an innovative method for the coating of graphite particles, typical of those used in lithium-ion batteries, with a nano layer of alumina

- In late November 2021, Altech achieved a breakthrough in lithium-ion technology with its research and development lab in Perth creating a workable graphite-silicon anode

READ the latest Batteries News shaping the battery market

Altech Chemicals achieves lithium-ion breakthrough as it advances plans to produce high purity alumina, November 30, 2021