Capacitive sensors are deemed to be only suitable for clean, dry environments. But the industrial capacitive sensors from Micro-Epsilon also impress in battery applications. They achieve submicron accuracy even in challenging environments.

With their temperature resistance, robustness and flexibility, capacitive sensors can be used in environments where fluctuating temperatures or magnetic fields occur.

High precision in high-tech applications

Capacitive sensors reliably measure displacements, distances and positions with submicrometer accuracy. They are used, among other things, for inline applications like film thickness or adhesive application measurement.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the battery economy!

Batteries News is the global go-to online magazine for the battery industry, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

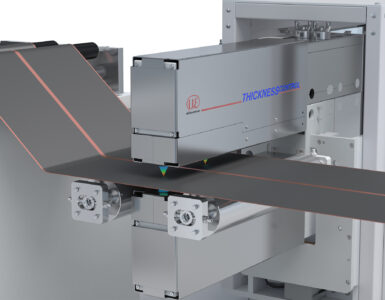

Two-sided thickness measurement of electrically conductive materials

In battery production, the thickness measurement of the battery film is of high importance. Two capacitive sensors mounted opposite each other enable two-sided thickness measurement. Strip thicknesses in the µm range can be measured using this method. Each of the two capacitive displacement sensors provides a linear distance signal which is calculated by the controller as a thickness measurement value. The measuring spot of the sensors is larger than that of the optical methods, which averages out any structures and anomalies on the surface. Using the capaNCDT multi-channel controllers enables processing of several sensor pairs with just one controller.

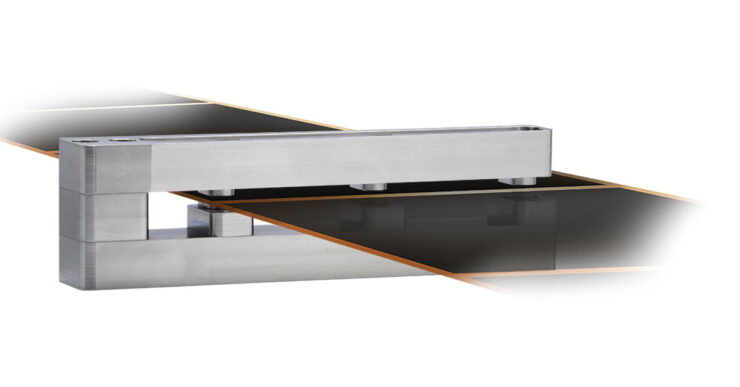

Two-sided thickness measurement with stable mounting frame

A mounting frame is available for multi-track thickness measurements with capacitive sensors. The frame enables even more precise measurement results and is used in the battery industry for two-sided thickness measurement of batteries as well as separator films. The sensors are located precisely on one axis here and are therefore congruent. Up to six sensors can be attached to one mounting frame. As two sensors each image a measuring point, up to three simultaneous measurements can be made at different points. The mounting frame is very temperature stable at temperatures up to 100 °C.

Ideal for confined spaces: capacitive PCB sensors with patented miniature connector

Micro-Epsilon offers extremely thin PCB-based sensors for these confined installation situations. The sensors are available with a height of 14 mm or 25 mm and have a miniature triaxial connector. Cable, sensor and connector are almost the same size here. At only 3.6 mm, the connector is about three times smaller than conventional connectors. This greatly simplifies integration of the sensor in machines and systems with particularly narrow installation spaces. The spiral sheath for the cables used offers additional protection against damage.

Precision through triaxial design

Unlike conventional capacitive sensors, sensors from Micro-Epsilon do not appear as with coaxial but as triaxial designs. This means that, in addition to the housing, the capacitor is also surrounded by a separately powered protective ring between the capacitor and the housing, which generates an electric field. This creates a homogeneous field between the measurement electrode and the object surface. The protective field around the measurement electrode prevents this field from spreading over other close conductive objects or other areas of the target. It inhibits other objects from influencing the measurement. This triaxial design makes the sensors more robust and considerably more accurate. Linearity is significantly improved and interferences of the measuring field are reliably prevented. In addition, these sensors can be flush mounted in conductive materials without generating a measuring error.

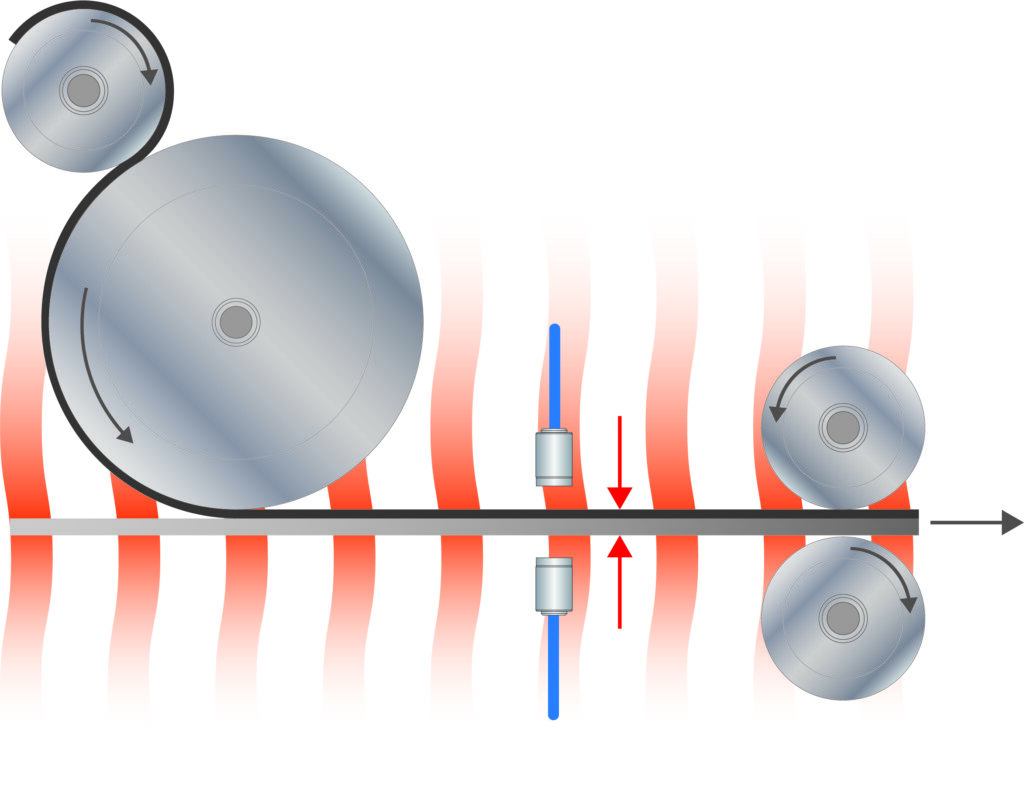

Two measuring principles – one sensor

The capacitive measuring principle is also ideally suited for combination with other measuring methods. Based on this, Micro-Epsilon has developed the combiSENSOR, which combines a capacitive with an inductive sensor on an eddy current basis. In battery production, it can measure non-conductive strip materials such as coatings. The sensors integrated in the sensor housing each measure the distance to the aluminum roller from the same side. The capacitive sensor uses the dielectric constant of the non-conductive material to determine the distance to the topside of the strip. The eddy current sensor determines the reference distance from the guide roller. In addition to high accuracy, high temperature stability is a decisive advantage. This means that thickness measurements can also be carried out in dry coating processes, for example.

Need help with the sensor selection? Configure your own capacitive system in just a few seconds! Click here

Author:

MICRO-EPSILON MESSTECHNIK GmbH & Co. KG

Michael Kuran, Expert for sensor technology in the battery industry

Franz Hochwimmer, Expert for system technology in the battery industry

Koenigbacher Str. 15, 94496 Ortenburg/Germany

Phone: +49 8542 168 0, Fax: +49 8542 168 90

www.micro-epsilon.com

READ the latest Batteries News shaping the battery market